Timing Belt Pulley Manufacturer From China | Yonghang

Timing Belt Pulley Manufacturer From China

We can produce all kinds of Timing belt Pulley.Including multi-ribbed pulleys, sprockets, and gears,Worm gear

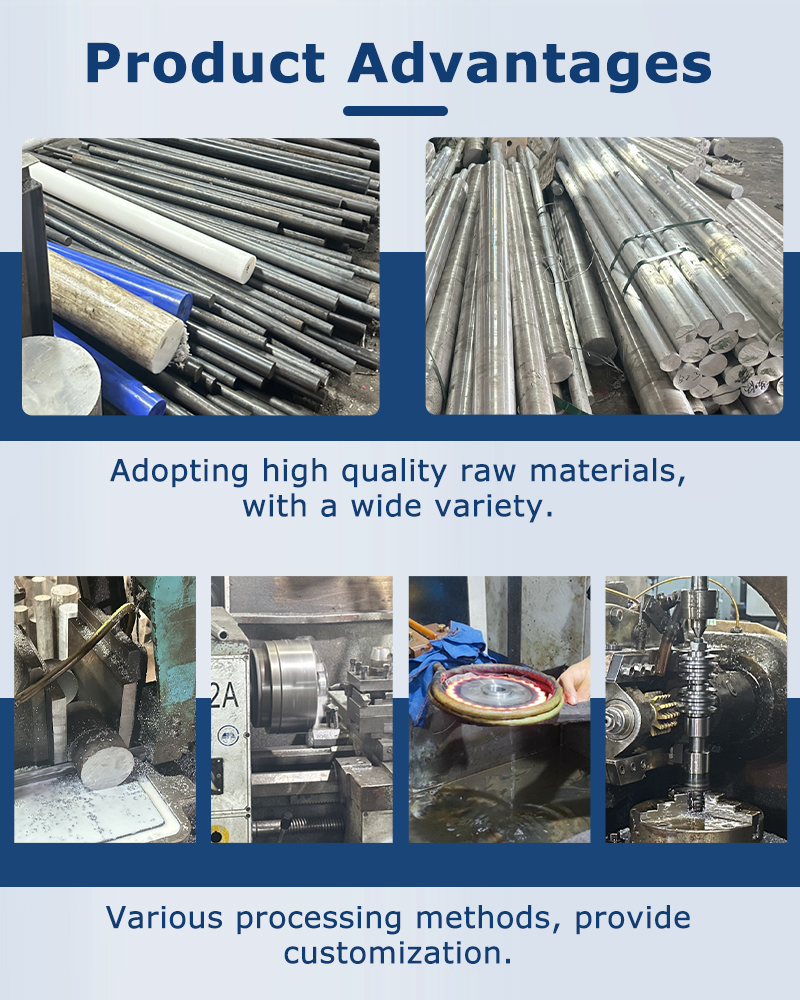

The materials include Aluminum alloy, Stainless steel, Brass, Plastic, No. 45 steel, etc.

URL video:http://www.yhbelt.com

WhatsApp&wechat:+ 0086 134 1810 3085

Email :sales@yhbelt.com

| Products Presentation/Parameters | ||

| Company | Guangzhou Yonghang Transmission Belt Co., Ltd. | |

| Product | timing belt Pulley | |

| NO. | Project | Result |

| 1 | Size: | Customized |

| 2 | Material: | Aluminium/Steel/Titanium alloy/Stainless steel/Barss/Plastic/POM |

| 3 | Type: | HTD STD T AT ATP BATK BAT RPP |

| 4 | Surface: | treatment and heat treatment for pulleys, Rust prevention process:oxidation gloss,Hard oxidation,oxidized matte,Black Anodize |

What is a timing pulley?

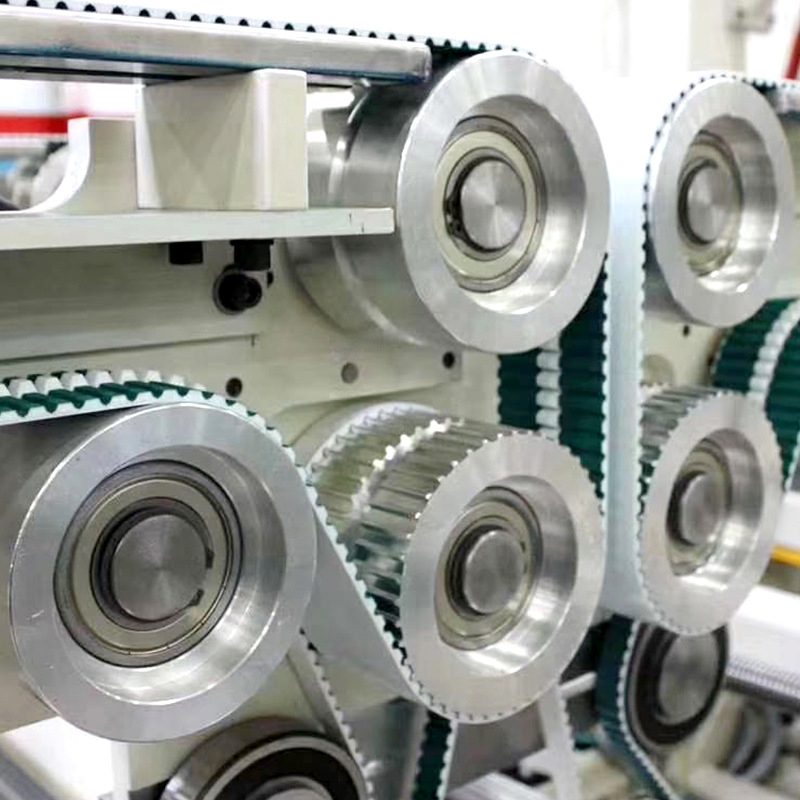

Timing pulleys have evenly spaced axial grooves cut in their periphery to make correct, positive engagement with the mating teeth of a timing belt in synchronous drives. They are used in power transmission systems where maintenance of speed ratio is an important design consideration. Synchronous belt drive systems are durable, highly efficient and suitable for many different applications.

Custom Timing Pulleys

Whether you need a proof-of-concept prototype or high-volume production, our team delivers with precision and reliability. Our engineering specialists are available to guide you through part selection, secondary operations, and custom design — ensuring optimal performance for your application.

Contact Engineering:

WhatsApp&wechat:+ 0086 134 1810 3085

Email :sales@yhbelt.com

Yonghang With the in-house engineering, design, and manufacturing expertise to produce custom, high-precision timing pulleys of any size, customized to suit any application. Yonghang Corporation provides quality, competitively-priced timing belt pulleys in a variety of styles and sizes.

We manufacture our quality timing pulleys from scratch right here in the China, ensuring our valued customers always have the pulleys they need, when they need them, at a truly competitive price. It is often better, faster and less expensive for you to have us make exactly what you need than it is for you to buy a unit off the shelf and then make the required modifications.

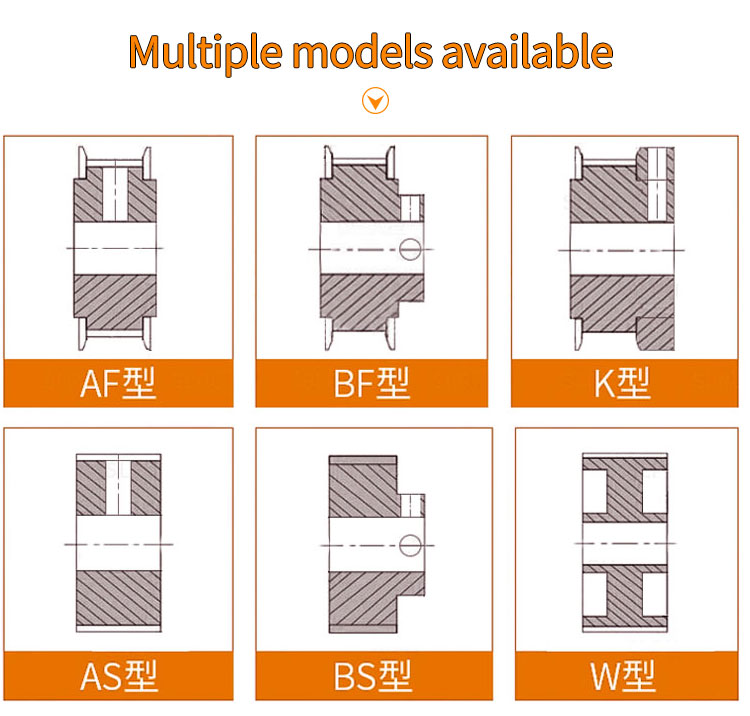

What type we can do?

AF BF AS BS K W

What material we can do?

Our pulleys are available in a wide variety of materials including steel, aluminum and plastic, Bronze, stainless steel. No. 45 steel and are custom-made to order.

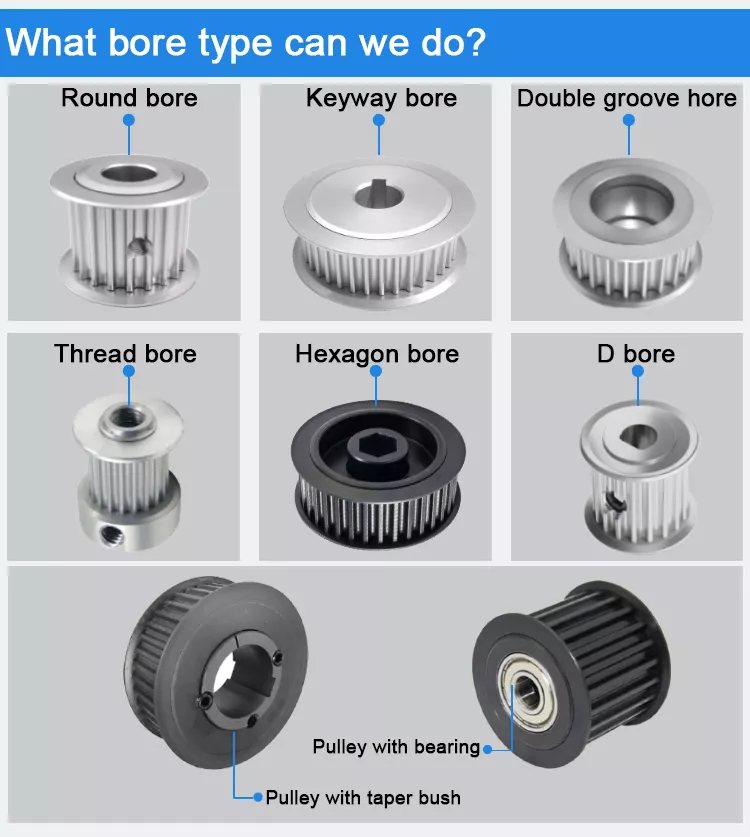

What bore we can do?

Round bore

Keywabore

Doube groovbore

Thread bore

Hexagon bore

D bore

Pulley with bearing

Pulley with taper bush

Rust prevention process

oxidation gloss

Hard oxidation

oxidized matte

Black Anodize

Quenching hardening

All Yonghang pulleys offer positive, non-slip drive, provide non-lubricated/clean operation, have a long life, are quiet, and have low maintenance requirements. All have minimum tooth-to-groove clearance (backlash) and are designed so that the teeth of the belt enter and leave the grooves with negligible friction.

Should you require a single pulley or a bulk order, in any standard or non-standard size, with any number of teeth, flanged or not, constructed of a specific material, or in any other configuration necessary to suit your needs, just let us know.

CNC Turning Services For Shaft Components

Completing this project would require a series of CNC Turning operations. A tight tolerance of .0005” total on all turned diameters needed to be maintained. Yonghang array of equipment includes advanced CNC Turning machines with the capability to produce precision components from 0.020” to 6” in diameter and lengths of up to 36”. Our machines can apply more than one hundred tools to a single part, giving us the ability to produce complex geometries and angles.

Our team of expert machinists was able to complete the order well within the customer’s production timeline and they were very satisfied with the results. For more information about CNC Turning services, contact the experts at Yonghang, today

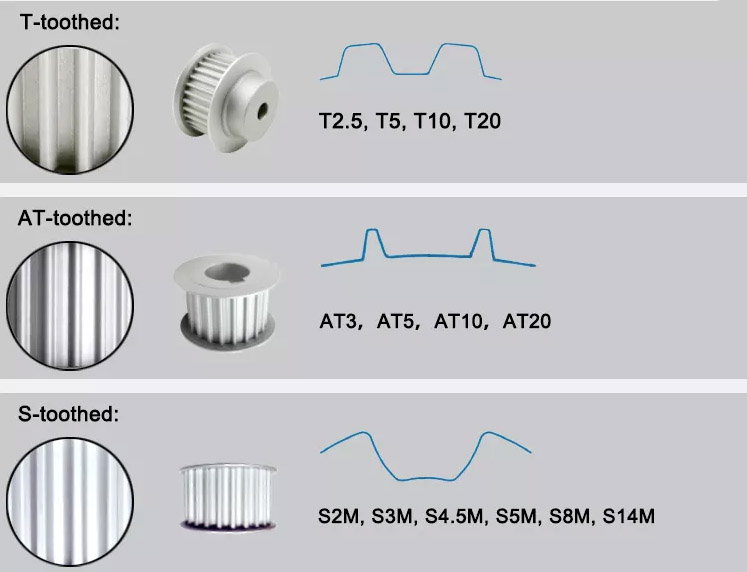

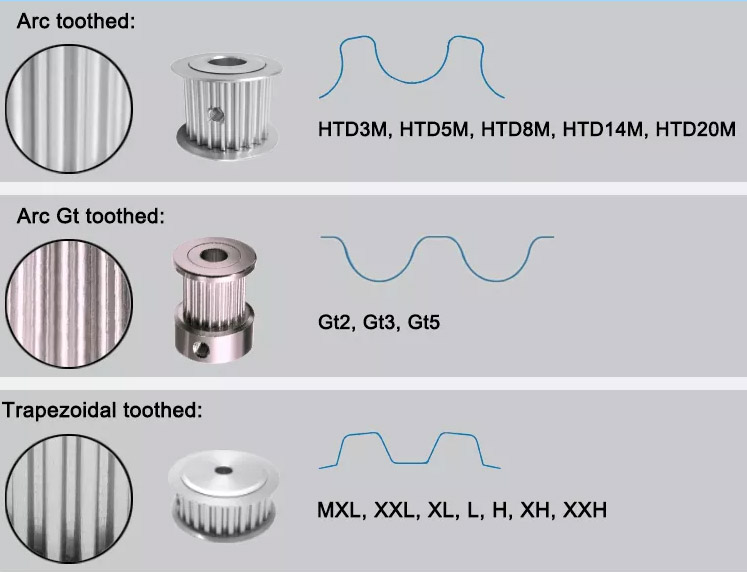

Available Timing Belt Pulleys Profiles:

MXL (0.080” Pitch) - Fine pitch, used for small mechanical systems or low-torque applications.

XL (1/5” Pitch) - Common in small power transmission systems, suitable for light-duty drives.

L (3/8” Pitch) - Typically used for general-purpose machinery and automation systems.

HTD (High Torque Drive) - Available in 3mm, 5mm, and 8mm pitches, HTD belts are designed for higher torque and better power transmission efficiency and are often used in CNC machines, robotics, and automotive systems.

STD: It adopts a flat-top semi-circular arc tooth profile ( tooth tops flat and arc-shaped sides), Is an upgraded version of HTD. It reduces stress concentration at the tooth root, making the transmission smoother and with lower noise.STD(S3M, S5M, S8M Pitch), and new specifications like S4.5M . It is suitable for high-precision equipment

GT2, GT3 (2mm, 3mm, 5mm Pitch) - GT (Gates Tooth) belts are designed for high precision and often used in 3D printers, robotics, and applications where positional accuracy is critical.

T (T Profile) - T2.5 (2.5mm), T5 (5mm), and T10 (10mm) profiles are often used in applications requiring a robust and efficient transmission system, such as in industrial machinery, automated conveyors, and other machinery where power and efficiency are essential.

Applications:

These timing belts and pulleys are used in a wide variety of industries, including:

CNC machines

3D printers

Robotics

Conveyor systems

Automated assembly lines

Automotive engines

Are you working on a specific application, or would you like more information on a particular timing belt profile or pulley option? Our engineers are available to provide friendly, expert advice.

Company Advantages

We are a factory with 20 years of International Trade and 15 years of manufacturing expertise in China. What we can offer you is not only quality also lower prices. We have CE, Rosh, and ISO9001 certifications. Additionally, for those components that come into direct contact with food surfaces, we have FDA certification. We look forward to working with you to expand the local market.

Contact Details