Yonghang Tooth Synchronous belts PU SFAT10 Timing belts

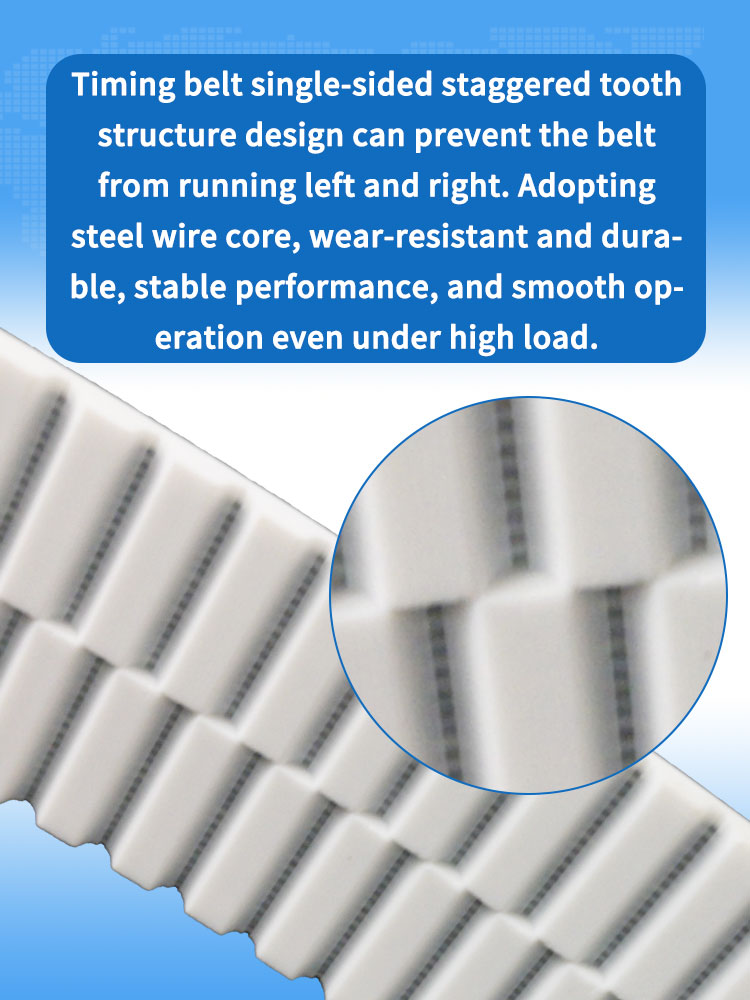

SFAT tooth profile SFAT is designed with AT-type properties, metric tooth pitch, trapezoidal belt teeth, and centre-crossed belt teeth. These belt teeth are staggered from each other. Combined with the combination of timing pulleys, the self-guiding allows the belt to move in a straight line without the need for a retaining ring.

Describe

SFAT10 Timing belt single-sided staggered toothstructure design can prevent the beltfrom running left and right. Adoptingsteel wire core, wear-resistant and dura-ble, stable performance, and smooth op.eration even under high load.

product information

| Tooth Profile | SFAT10 |

| Tooth Pitch t [mm] | 10 |

| Tooth Height h [mm] | 2.5 |

| Base Belt Thickness H [mm] | 2 |

| Tolerance [mm] | +/- 0.5 |

| Hardness | 92 Shore A |

| Tensile Members | Steel |

| Color | White/Yellow/black/gray |

| Minimum of Teeth on Pulley | 15 |

| Minimum Pulley Diameter [mm] | 50 |

| Steel Tension Member [N/10 mm] | 1600 |

| Stainless Steel Tension Member [N/10 mm] | 1152 |

| Tooth Angle 2β [°] | 50 |

| Unit Mass kg/m [: 10mm] | 0.058 |

Standard Widths [mm]:

25, 32, 50, 75, 100, 150 mm In between widths available

Standard Lengths [mm]:

SFAT10 Self Tracking Timing Belts are most commonly offered in lengths of 1100, 1200,1300,1400,1500,1600,1700,1800,1900, 2000,2500,2800, 3000,3550,4000, 4500,5000, 5300, 5600, 6000 mm,while custom sizes (lengths, widths and pitches) are available upon request.

SFAT10 Self Tracking PU Synchronous Belts usually consist of polyurethane body and steel cord, while custom materials available upon request. Special cords include aramid (kevlar), stainless steel and carbon fiber.

Options join

Truly Endless (Flex/Moulded) –YONGHANG– Power Transmission

Endless with joint

Open Ended

Pin Join

Steel + (PAZ, PAR, PAZ/PAR)

Tensile Members

Steel

Aramid Kevlar

Stainless steel

Materials

SFAT10 Self Tracking Timing Belts combine steel reinforcement, It provide accuracy and linear drive. Self-tracking timing belts are made with two materials:

Wear resistant polyurethane +High tensile steel cord tension members.

Polyamide fabric+ Synthetic pu teeth

Advantages

– Continuous tooth engagement

– Friction reduced tracking

– Smooth idler interaction

– Smooth meshing of belt and pulleys

– Increased power range

– Improved repeatability

– Self-tracking, no flanges necessary

– Decreased polygonal effect

– More compact design

– Tangential belt drive possible

– Reduced vibration

– Reduced noise

– No lateral movement

Applications

– Conveying

– Indexing

– Linear drives

– Power transmission

Mechanical properties

– Friction / adhesion

– Abrasion resistance

– Wear resistance

– Release

– Cut resistance

– Compressibility

Physical properties

– Antistatic

– Electrical conductivity

– Flame retardant

– Cold resistance

– Hydrolysis resistance

Chemical properties

– Oil and fat resistance

– Food approved

– Easy to clean

– Acid and base resistance

– Ozone and UV resistance

Contact Details