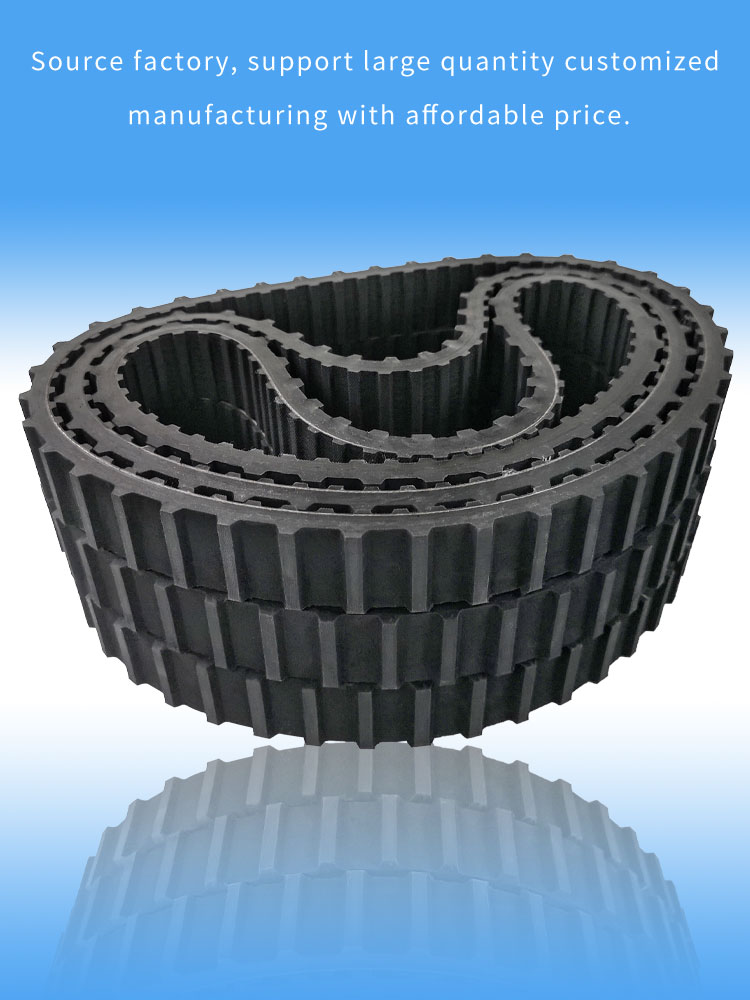

Yonghangbelt special customized rubber timing caterpillar track belts for jack

Rubber timing tracks belts are transmission components specifically designed for jacking devices, automated lifting mechanisms, and various equipment requiring precise linear motion. They innovatively combine the precise transmission characteristics of timing belts with the continuous support and efficient load-bearing capacity of tracks.

Description

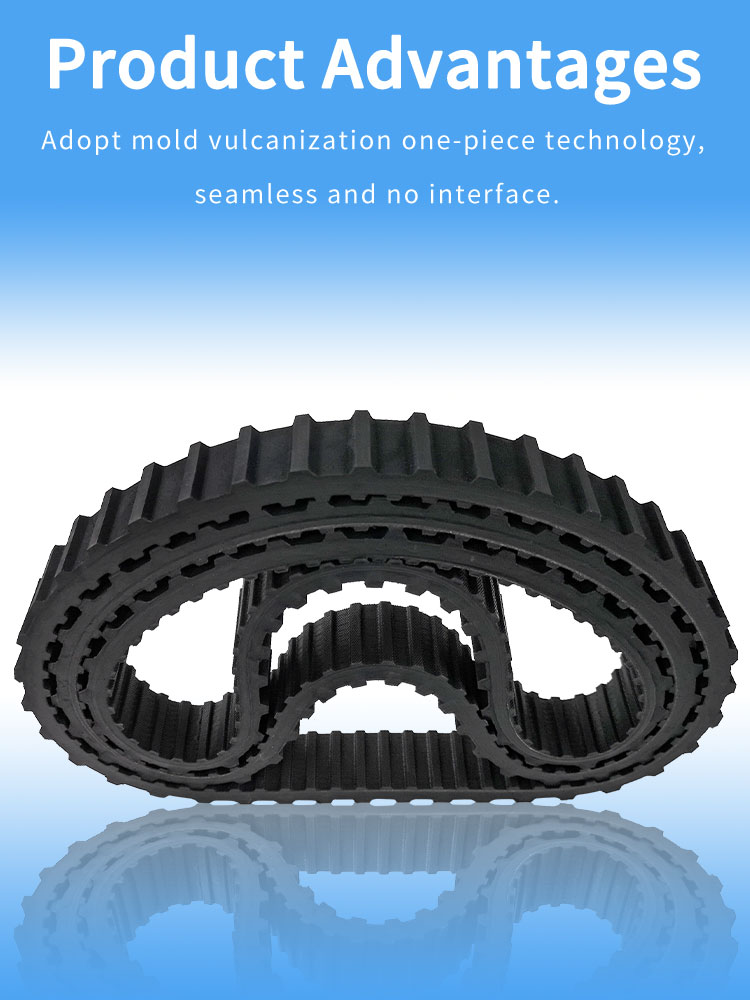

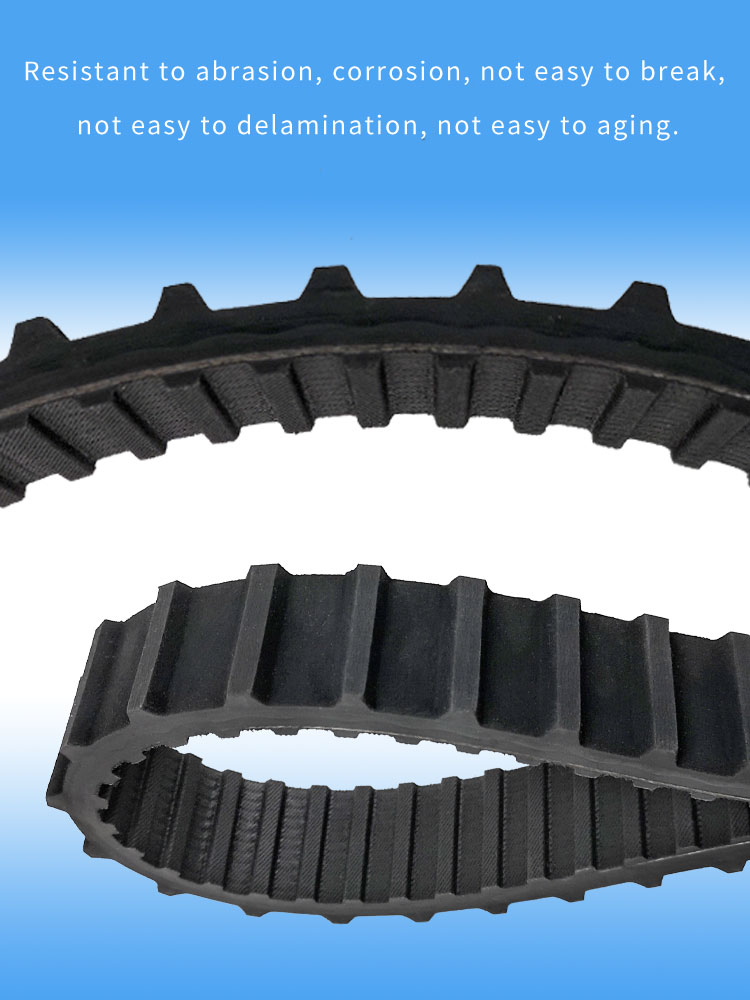

Constructed primarily from high-strength neoprene rubber, these tracks incorporate internal glass fiber reinforcement for tensile strength, ensuring high durability and low elongation. Their tooth profiles—such as HTD, S3M, and S5M curved teeth—achieve perfect meshing with pulleys, enabling slip-free synchronous transmission with minimal backlash and high positioning accuracy.

✨ Core Advantages

Compared to traditional transmission methods, rubber timing tracks belts offer significant advantages in lifting applications:

Exceptional load capacity: The wide track contact area evenly distributes load pressure. Combined with a robust internal reinforcement skeleton, it can support loads of several tons, making it ideal for heavy-duty lifting equipment.

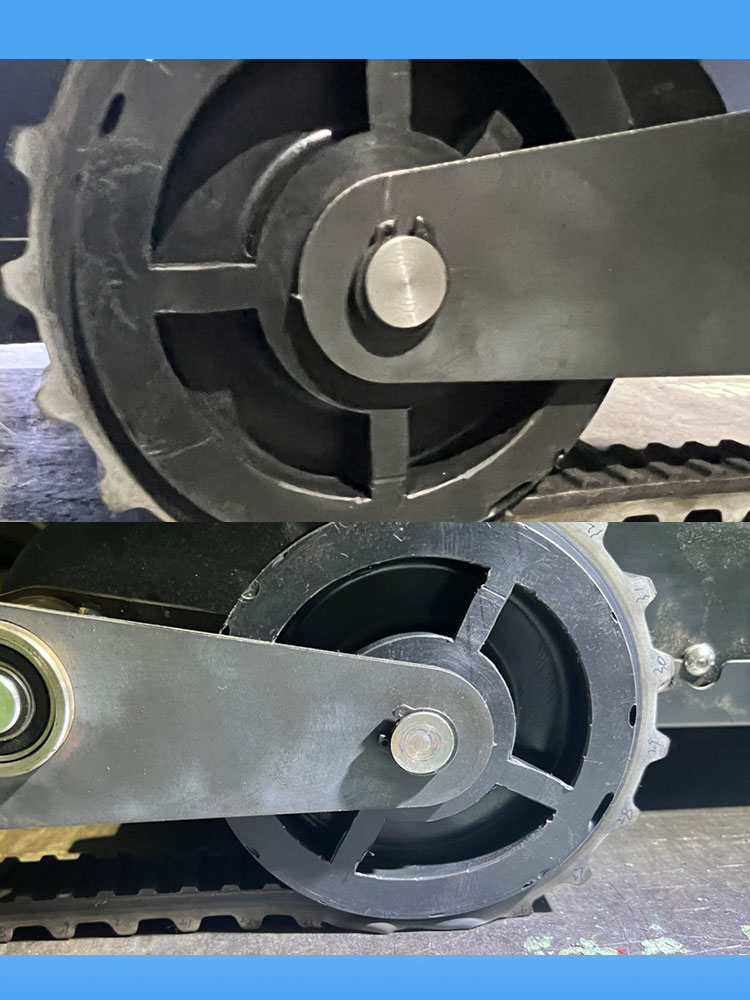

Precise Synchronized Drive: Like a synchronous belt, it transmits power through toothed engagement, completely eliminating slippage. This ensures precise control of lifting height and high repeatability in positioning accuracy.

Smooth and Quiet Operation: Rubber material effectively absorbs and dampens vibrations and impacts during operation, ensuring a smoother lifting process with significantly lower noise levels compared to chain or gear drives.

Outstanding Durability and Low Maintenance: The product features a long service life and requires virtually no maintenance. It resists aging and ozone erosion, handles high-load cyclic operations, and reduces maintenance costs.

Exceptional Environmental Adaptability: Ground pressure as low as 50 kPa delivers outstanding performance across diverse terrains. Yonghang models feature specialized rubber formulations and structural designs for resistance to oil, acids, alkalis, and salt corrosion.

Application Scenarios

Rubber synchronous tracks are widely used in lifting and linear transmission mechanisms across the following fields:

Industrial Lifting Equipment: Elevating units for lifting platforms, hoists, and robotic grippers on automated production lines, as well as Z-axis drives for 3D printers and scanning devices.

Heavy Machinery: Serving as travel components for compact excavators, tractors, and small mountain loaders, delivering robust traction and support.

High-Precision Positioning Systems: Enabling stable, reliable linear motion in equipment requiring precise positioning, such as wafer handling robots, LCD panel transfer equipment, and pick-and-place machines.

Specialized Vehicles & Rescue Equipment: Serving as the mobility system for rescue vehicles, disaster relief vehicles, light armored vehicles, and tracked robots, delivering all-terrain traversal capability.It can also be used as the tracks of a tunnel exploration robot to penetrate into small tunnels for exploration.

Contact Details