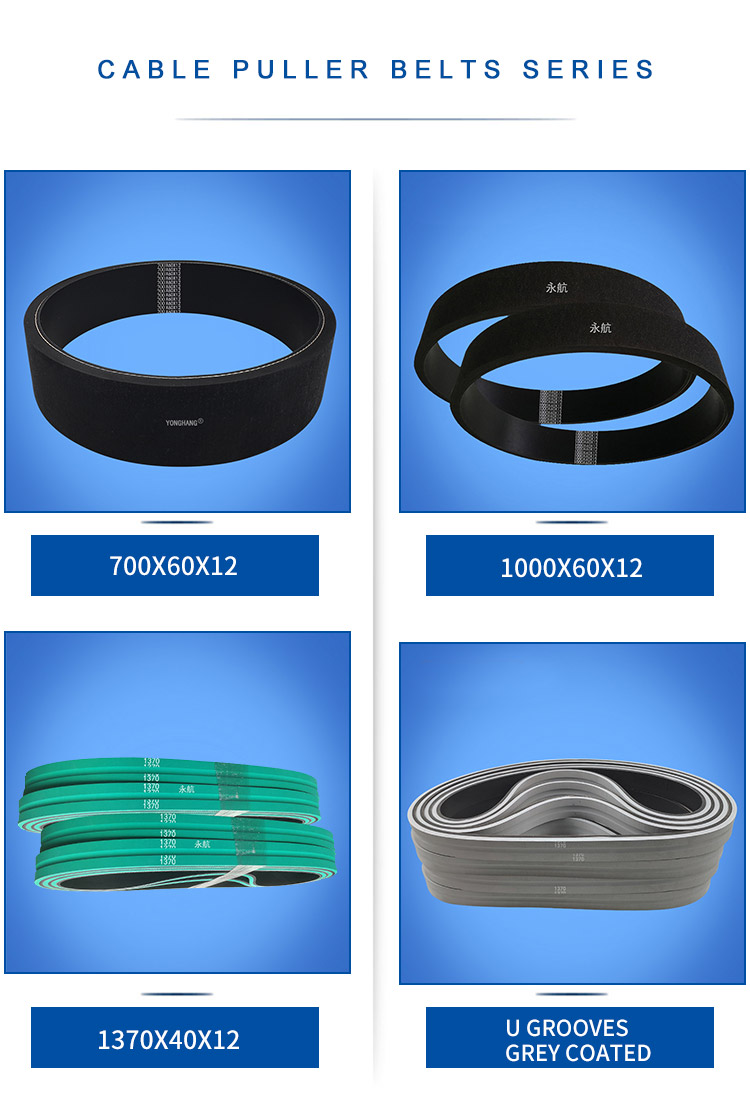

industrial extrusion cable caterpillar haul off rubber belt power traction drive puller belts with surface grooving

industrial extrusion cable caterpillar haul off rubber belt power traction drive puller belts with surface grooving

YONGHANG supplies Haul-off belts for all types of extruders, including caterpillar haul-off for cables, wires, pipes and profiles.

Haul-offs” are pulley-driven parallel belts that contact opposite sides of in-process products, usually by means of rollers exerting suitable pressure for the belts to grip and haul them, with the desired controlled pulling action.

Our range includes specific combination of base belts, tensile strengths and fabrication details to meet technical requirements of variety of extrusion applications, including specific resistance, hardness, temperature, friction needs.

Please contact us direct for more information regarding your specific requirements.

industrial extrusion cable caterpillar haul off rubber belt power traction drive puller belts with surface grooving

| Product informatie Rubber | |

| Specification(Inner Length, Width, Thickness) | Customization |

| Ribs type | PK /PJ/PL/PM /Flat |

| Color | Black |

| Traction Layer | Rubber: Imported NR |

| Bottom layer | Rubber: CR ;neoprene Reinforcement: Polyester Cord + Fabric |

| Mechanical Properties | High breaking load; High Wear Resistance; Low Elongation at Working Load; Aging Proof |

| Hardness | 60-85°± 5°(cable traction) 60-85°± 5°(optical cable; plastic and pipe Traction etc.) |

| Max. temperature | +100℃ |

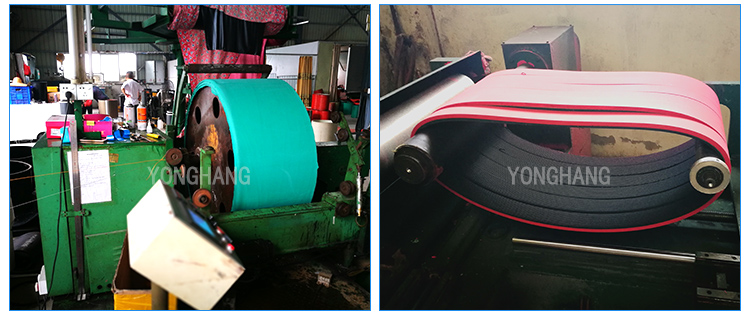

| Processing | Rubber Mixing, Winding,Rubber Adding, Cutting,Grinding, QC, Packaging and Delivering |

| Application | Cable, Optical cable, Plastic, Rubber tube, Pipe, Seal and Packaging industry etc. |

Yonghangbelts supplies a wide range of haul-off belts which ensure high resistance to abrasion, excellent grip properties and a precise finishing that guarantee an homogeneous coating, for a perfect adherence to the extruded material.

Haul-off belts are available with covers resistant against most oils, greases and acids, as well as suitable for high temperature or provided of coating for non-marking application. Further available application are: millings, transversal notches which increase flexibility of the belt whilst reducing the winding diameter on the pulley, longitudinal grooves.

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details