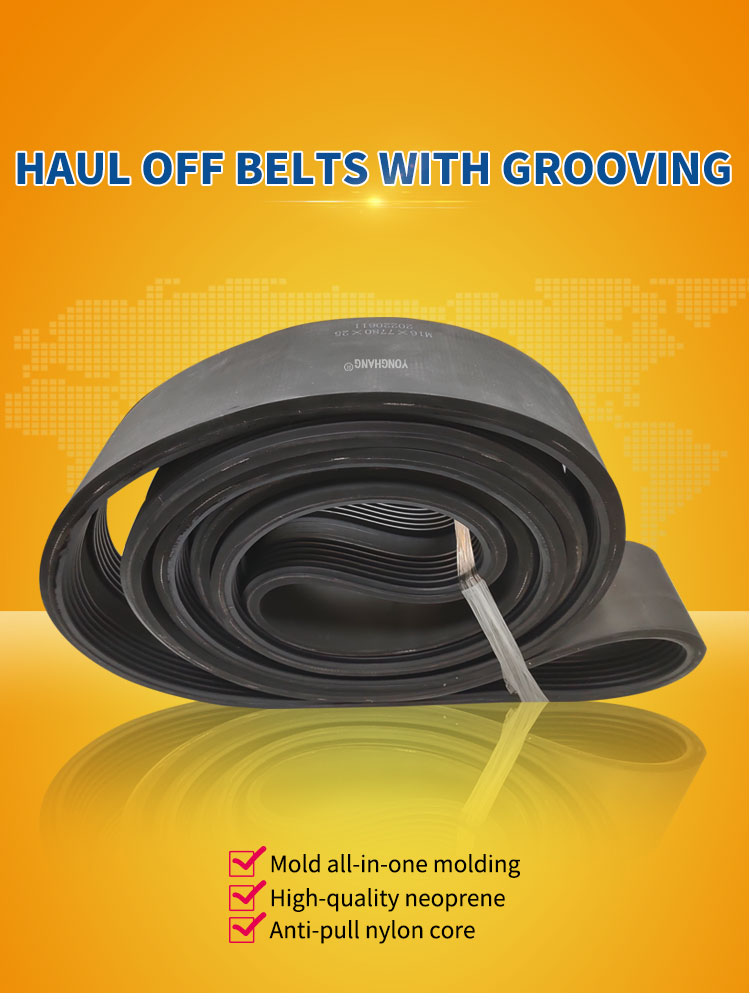

wear-resisting grooving rubber caterpillar belts

Cable wire pipes and plastic profiles wear-resisting grooving rubber caterpillar belts extrusion haul-off units belts

lay and haul cables of all types, extruded profiles, steel cords, pipes and hoses with a high degree of precision. These belts are oil & grease resistant & temperature resistant to 110°C. Haul-Off Belts are fabricated using either a Poly V (micro-vee) base belt, Flat Synthetic Rubber Belt or a Timing Belt as the base belt. A range of top cover accurate tolerance rubber coatings are then applied. The finish & hardness of the rubber cover is determined by the application. Additional services include slitting, profile grinding, perforating, slotting & tooth removal.

Cable wire pipes and plastic profiles wear-resisting grooving rubber caterpillar belts extrusion haul-off units belts

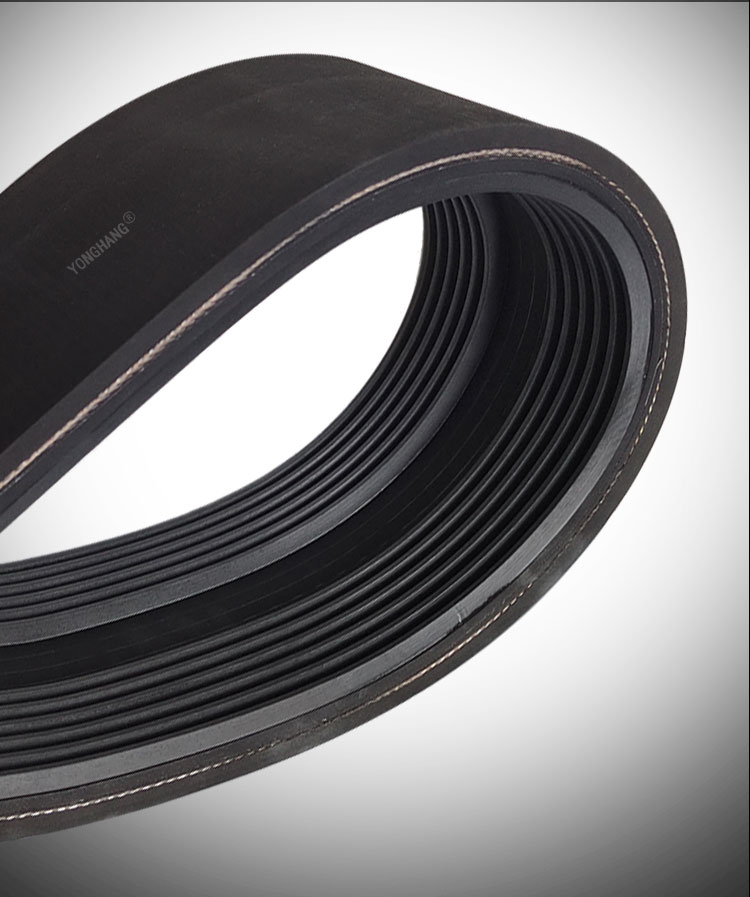

tooth removal caterpillar belts is a specialized conveyor belt custom-made for cable factory cable production lines. The tooth removal is removed to secure the guide strips and prevent misalignment. It is integrally vulcanized to ensure no delamination, high resistance to breakage, and exceptional wear resistance.

Here is one of the cases we have conducted. Not all products are included. The length range we can handle is from 1000mm to 10000mm, the width ranges from 50mm to 550mm, and the thickness range is from 10mm to 35mm. If you need to know more information, please contact us.

Yonghang transmission belt has been specializing in the production of rubber caterpillar belts extrusion haul-off belts for 20 years.

| Specification(Inner Length, Width, Thickness) | Customization / PJ PK PL PM ribs type |

| Color | Black |

| Traction Layer | Rubber: Imported NR |

| Bottom layer | Rubber: CR ; Reinforcement: Polyester Cord + Fabric |

| Mechanical Properties | High breaking load; High Wear Resistance; Low Elongation at Working Load; Aging Proof |

| Hardness | 60°± 5°(cable traction) 50°± 5°(optical cable; plastic and pipe Traction etc.) 80°± 5°(custom) |

| Max. temperature | +110℃ |

| Delievery Time | Depend on Quantity and Model |

| Processing | Rubber Mixing, Winding,Rubber Adding, Cutting,Grinding, QC, Packaging and Delivering |

| Application | Cable, Optical cable, Plastic, Rubber tube, Pipe, Seal and Packaging industry etc. |

Guangzhou Yonghang Transmission Belt Co., Ltd. was founded in 2014, is a focus on rubber belt research and

development manufacturer. Yonghang company has 10000 square meters of production base, the introduction

of domestic and foreign advanced manufacturing equipment more than 50 units, and so on. Mold more than

8000 sets, an annual output of various types of rubber belt 500,000. The main products for the rubber belt series

of products, such as coated timing belt, rubber flat belt, rubber haul off belt, PU timing belt, ATM belt, sausage

machine belt, printer Belt, and so on.

YONGHANG company strictly implements IS09001 international quality certification, from design, raw materials,

to production, every detail is excellence, only for high quality! Our products are widely used in printing carton

packaging equipment, pipe wire and cable traction equipment, food packaging film equipment, wood chopsticks

carpentry equipment, and so on.

YONGHANG offers a wide variety of standard items and special products designed to satisfy specific customer requirements.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers

high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to

settle any after-sale issues.

Contact Details