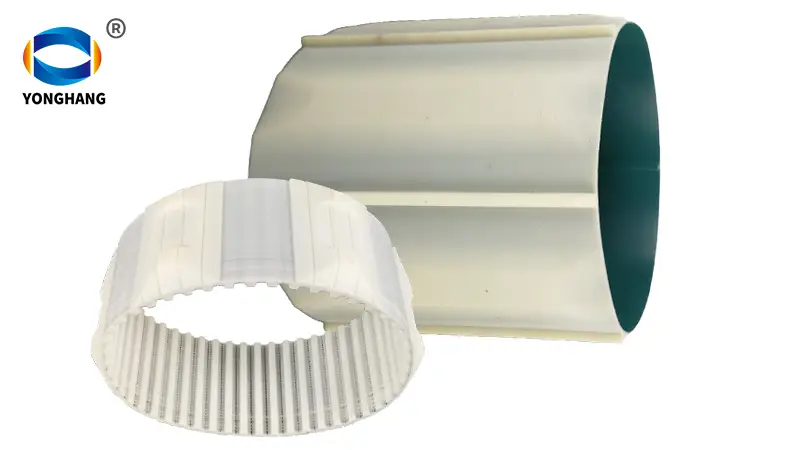

T10-480-74mm T10-480-190mm seamless cpu timing belt cleats for tobacco industry

Seamless CPU timing belts in the tobacco industry have the following characteristics:

High durability: Seamless CPU timing belts are usually made of high-strength materials that can withstand the high temperatures, high humidity and chemical corrosion in the tobacco production process, ensuring long-term stable operation.

Precise synchronization: These synchronous belts are designed to provide precise transmission, ensuring the coordination of all aspects of the equipment in the production process, reducing errors and increasing productivity.

Seamless CPU timing belts in the tobacco industry have the following characteristics:

High durability: Seamless CPU timing belts are usually made of high-strength materials that can withstand the high temperatures, high humidity and chemical corrosion in the tobacco production process, ensuring long-term stable operation.

Precise synchronization: These synchronous belts are designed to provide precise transmission, ensuring the coordination of all aspects of the equipment in the production process, reducing errors and increasing productivity.

Low noise operation: The seamless design reduces friction at the seams and lowers noise during operation, improving the working environment and meeting the requirements of modern production.

Easy to maintain: the structure of seamless CPU synchronous belt makes it easier to maintain and replace, reducing downtime and improving the overall efficiency of the production line.

Strong adaptability: able to adapt to different types of tobacco processing equipment, suitable for production lines for a wide range of products such as cigarettes and tobacco.

High tensile strength: the seamless design enhances the overall strength of the belt body, which is able to withstand large tensile force and suitable for high load working environment.

Reduced sliding: Due to the seamless design, the sliding phenomenon between the belt and the wheel is reduced, which improves the transmission efficiency and reduces energy consumption.

Contact Details