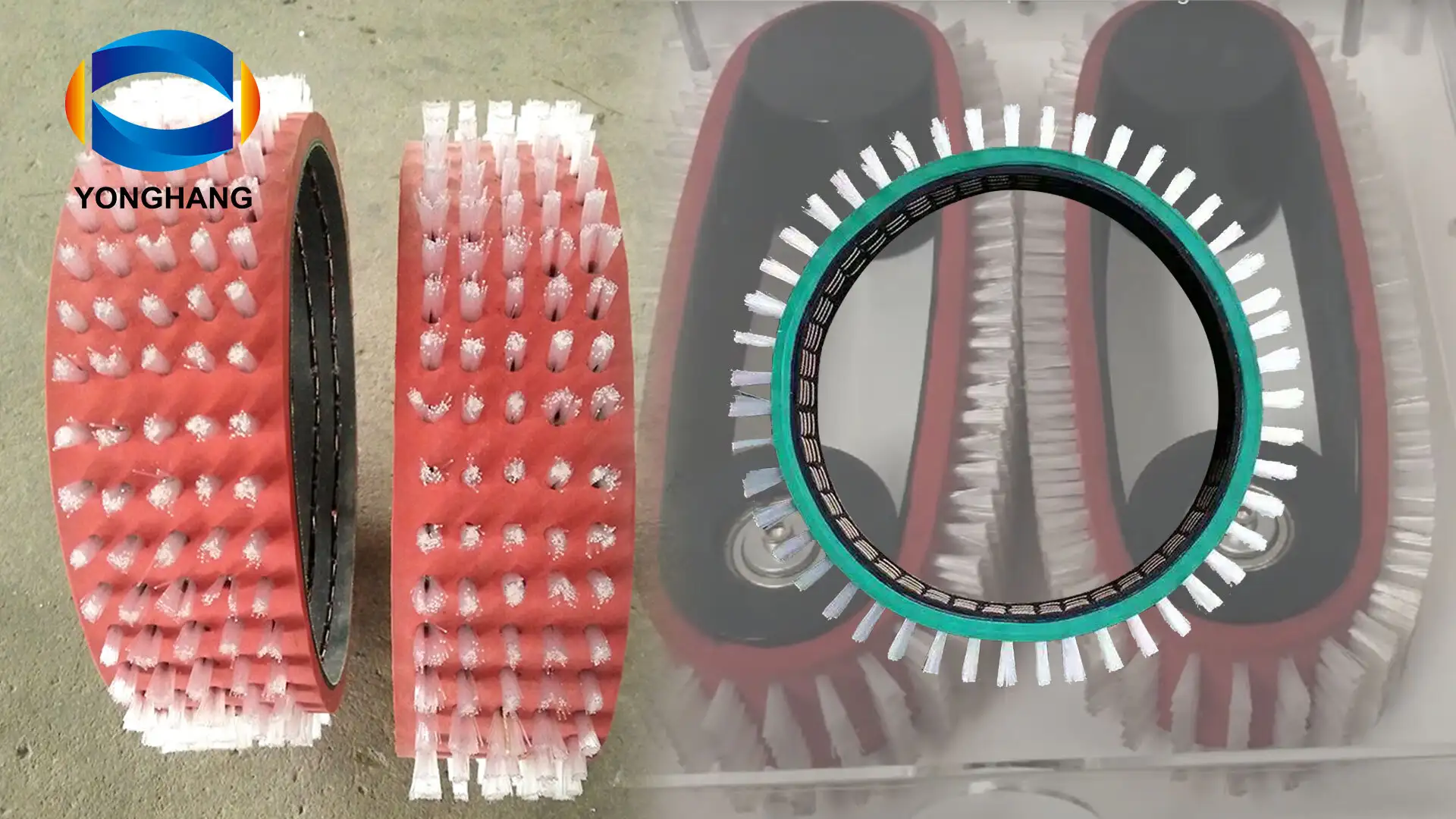

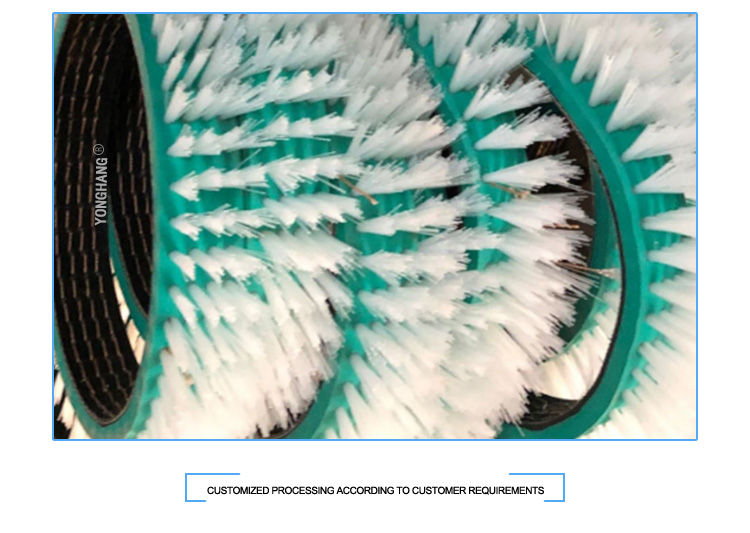

long brushes braid shield untwist machine belt Wire Brushing Machine belt

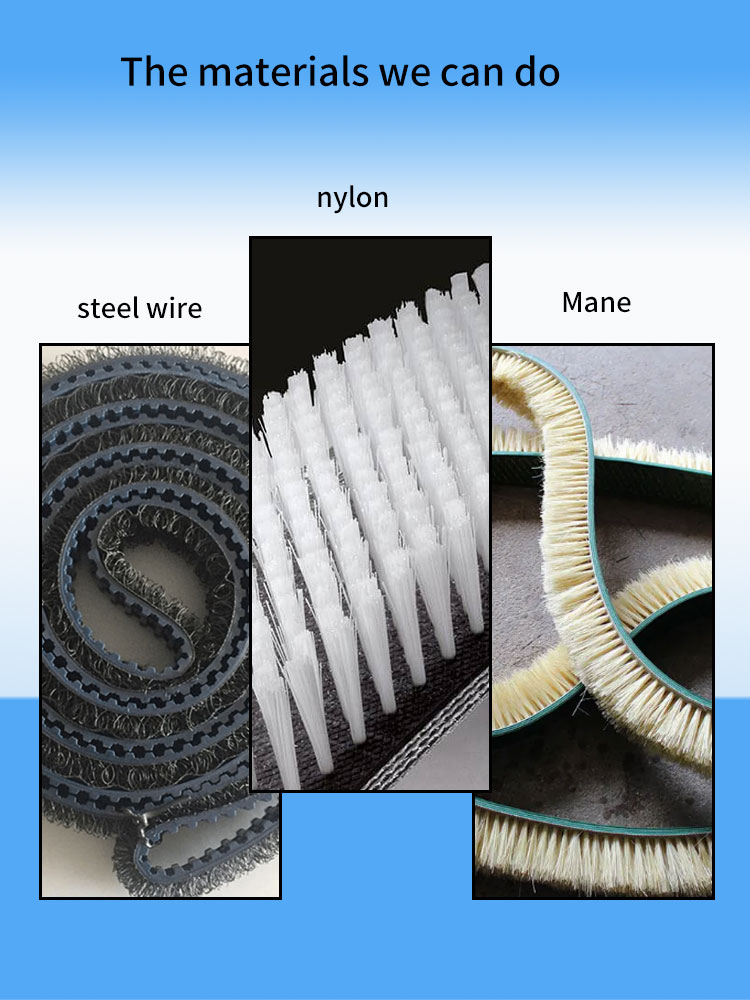

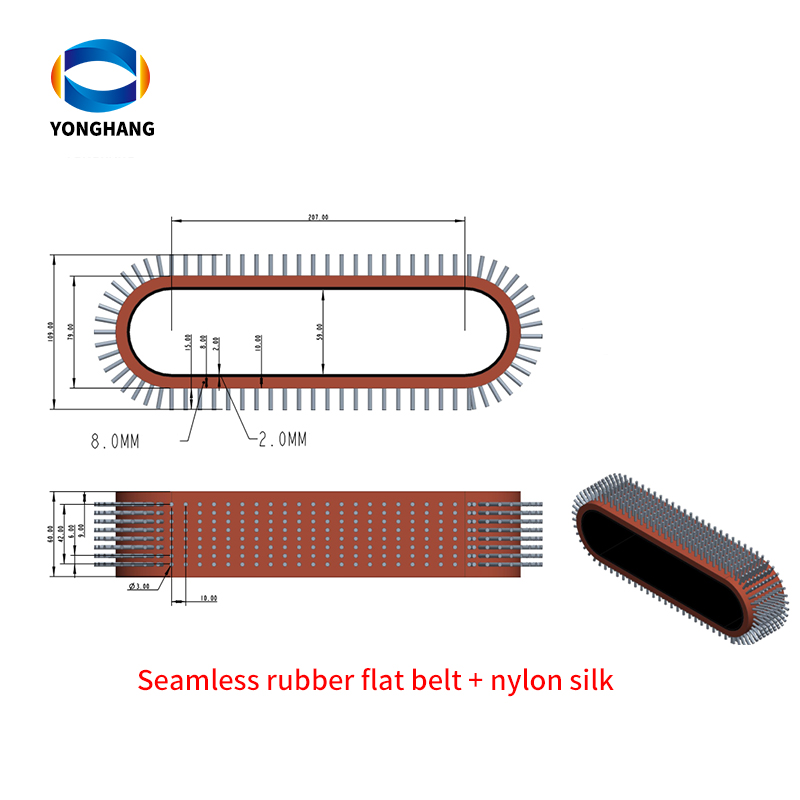

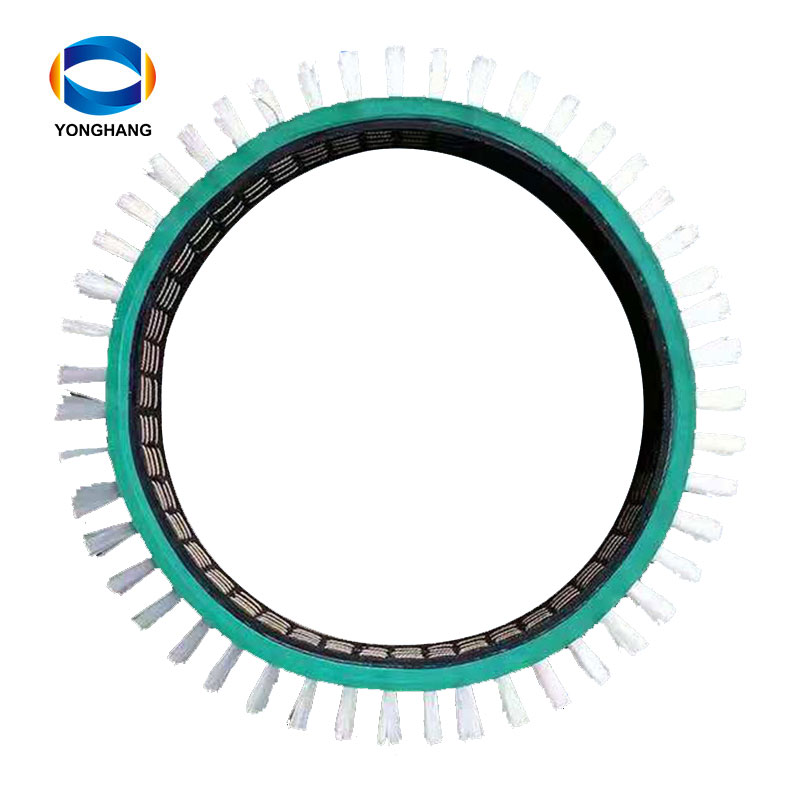

This product can be made seamless and jointed loop two kinds of bottom belt, the length of flocking according to customer requirements from 2mm-30mm, ranging from 0.1mm-1mm, flocking materials are nylon, copper wire, steel wire, bristle and so on, if you do not have the product you want below, please contact us for advice.

Wire brushing machine belts are available in a variety of materials, each with its own unique properties and benefits. Some of the most common materials used in these belts include:

Rubber - Rubber is a common material used in wire brushing machine belts due to its high elasticity and durability. Rubber belts can withstand high levels of tension and are resistant to abrasion and wear.

Polyurethane - Polyurethane is a popular choice for wire brushing machine belts due to its excellent resistance to chemicals, oils, and solvents. Polyurethane belts are also highly resistant to abrasion and can operate at high speeds.

Nylon - Nylon is a strong and durable material that is commonly used in wire brushing machine belts. Nylon belts are highly resistant to abrasion and have a high strength-to-weight ratio, making them an ideal choice for heavy-duty applications.

Stainless Steel - Stainless steel is a material that is commonly used in wire brushing machine belts due to its high strength and corrosion resistance. Stainless steel belts are highly durable and can operate at high temperatures without losing their strength or shape.

Choosing the right material for a wire brushing machine belt will depend on a variety of factors, including the operating environment, the amount of power that needs to be transferred, and the level of precision required. By selecting the right material, users can ensure that their wire brushing machine operates efficiently and effectively, providing high-quality results while minimizing downtime and maintenance costs.

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details