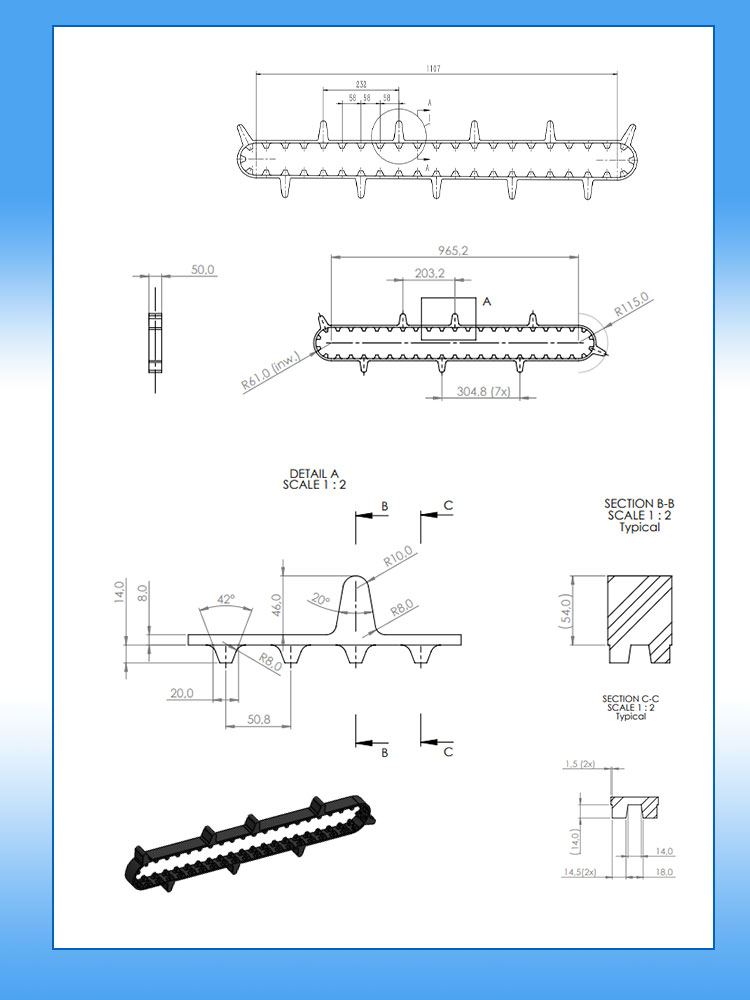

Corn harvester rubber 11 10 8 7 blocks agriculture track timing transport belts for CLAAS Agricultural Equipment

Agriculture track timing transport belts is a closed-loop track assembly specifically engineered for agricultural machinery, composed of rubber and reinforced materials. It primarily consists of four components: the core, reinforcement layer, cushion layer, and rubber sections. Utilizing specialized rubber formulations and manufacturing techniques, it ensures exceptional durability and reliability even under harsh agricultural conditions.

CLAAS Corn harvester 11 blocks track belt

CLAAS Corn harvester 10 blocks track belt

CLAAS Corn harvester 7 blocks rubber belt

CLAAS Corn harvester 8 blocks transport belts

Yonghang corn harvester rubber tracks transport belts utilize a seamless molded vulcanization process without joints, significantly enhancing peel resistance and overall service life. They are particularly suitable for harvesting root crops like corn.

Product Advantages

Exceptional Durability and Low Maintenance

Featuring an agricultural machinery-specific rubber compound and high-strength reinforcement (Kevlar cord), it delivers outstanding resistance to abrasion, tearing, flexing, and punctures. Requires only one or two tension adjustments during operation, significantly reducing maintenance frequency and costs.

High Efficiency and Crop Protection

Rubber tracks transport belts operate with low noise and minimal vibration, enhancing operator comfort. Simultaneously, they effectively minimize soil compaction around corn roots and stems, preventing crop damage.

Excellent Compatibility and Cost-Effectiveness

Designed for broad versatility, these tracks are compatible with various mainstream brands of corn harvesters, carrot harvesters, tractors, and other agricultural machinery. Yonghang Transmission Belts significantly reduce production costs, offering prices at just 50%–60% of imported products for outstanding value.

Applications

Harvesting Various Root Crops: Its design effectively minimizes damage to crops like root vegetables, while also being suitable for harvesting soybeans, peanuts, potatoes, radishes, and other root crops. Optimized design reduces skin damage and missed harvests.

Other combine harvester belts

As a critical component of combine harvesters, we also manufacture rubber tracks belts. These tracks adapt to muddy fields caused by frequent flooding, solving issues like wheeled machinery getting stuck or slipping. They ensure timely corn harvesting by providing reliable traction for the harvester's movement.

The rubber tracks belts produced by our Yonghang factory,Modified designs like triangular tracks are particularly suited for challenging terrains such as loess hills, terraced fields, and waterlogged cornfields. They offer superior traction and driving force, significantly enhancing operational efficiency in complex terrain.

Contact Details