Coated timing belt for pull down vacuum machine sale by bulk

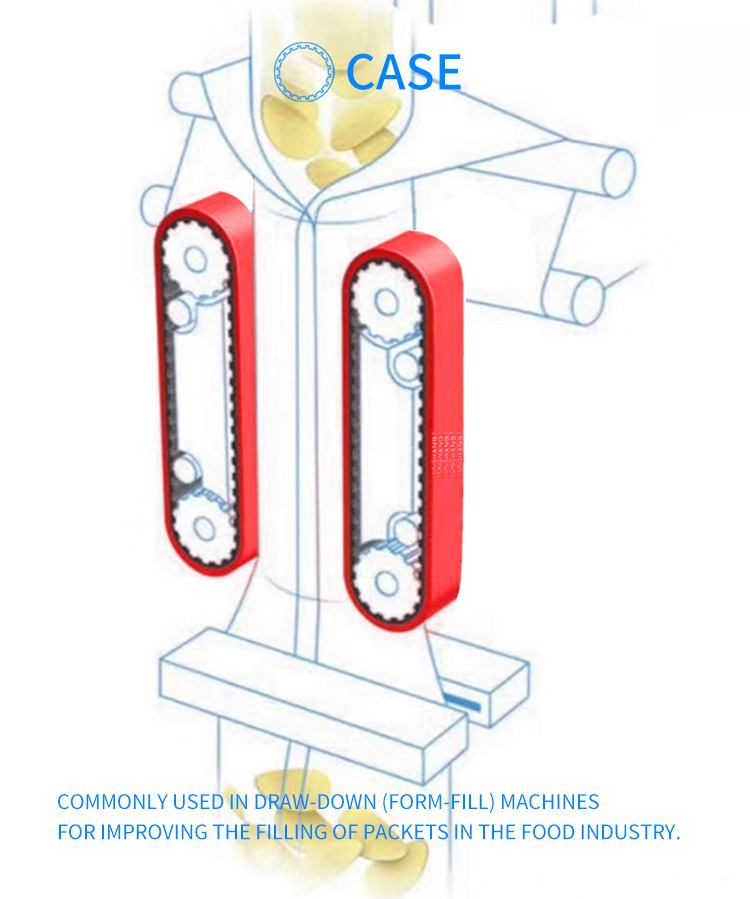

Rubber Coated Timing Belts are used in form fill seal machines to pull down plastic foil to form a pouch or a bag into which the product to be packed. The packets are gripped and drawn down by two specially constructed belts, usually located vertically for easier filling control of the product. Our top Natural Rubber coated belts ensure good co-efficient of friction, designed to meet particular needs, with good release or grip qualities – depending on the requirements.

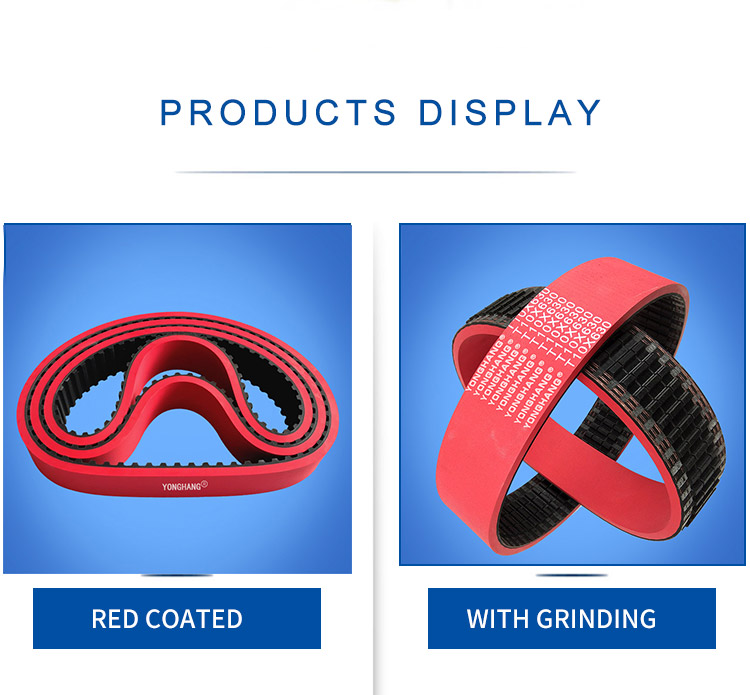

The drawn down belt consists of a basic toothed belt in PU or Rubber material and a cover on top. The basic belt is around 90 ShA while the cover should be much softer ranging from 35-55 ShA to pull the foil or paper they draw for packaging the product into a bag.Various sizes with different coating thickness are available ex-stock.

Offered belts that are commonly used in draw-down (form-fill) machines for improving the filling of packets in the food industry.The packets are first gripped and then drawn by 2 belts located vertically for easier filling control of the products.The belts are natural rubber coated or linatex coated ensuring the high coefficient of friction. The belt is designed for good release or grip depending upon the requirements. The belts are available in different sizes with varied coating thickness.Provided belts are used for VFFS machines

adopt mould one - piece vulcanization molding process.

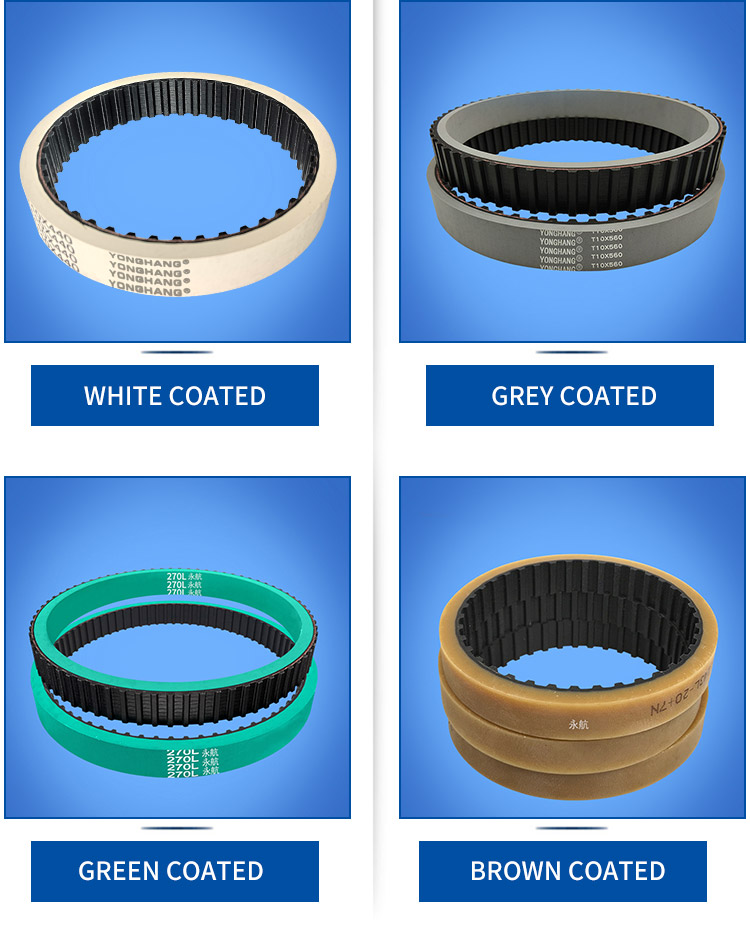

offers a wide range of coatings.For each application

there is a suitable coating to achieve a desired

coefficient of friction, abrasion resistance,

or thickness.And with a high-strength fiber rope,

tensile strength increased by 35%! Ensure that the use

of the process will not break longitudinally,

not delamination, strong friction, not easy to stretch,

wear-resistant and durable, longer life!

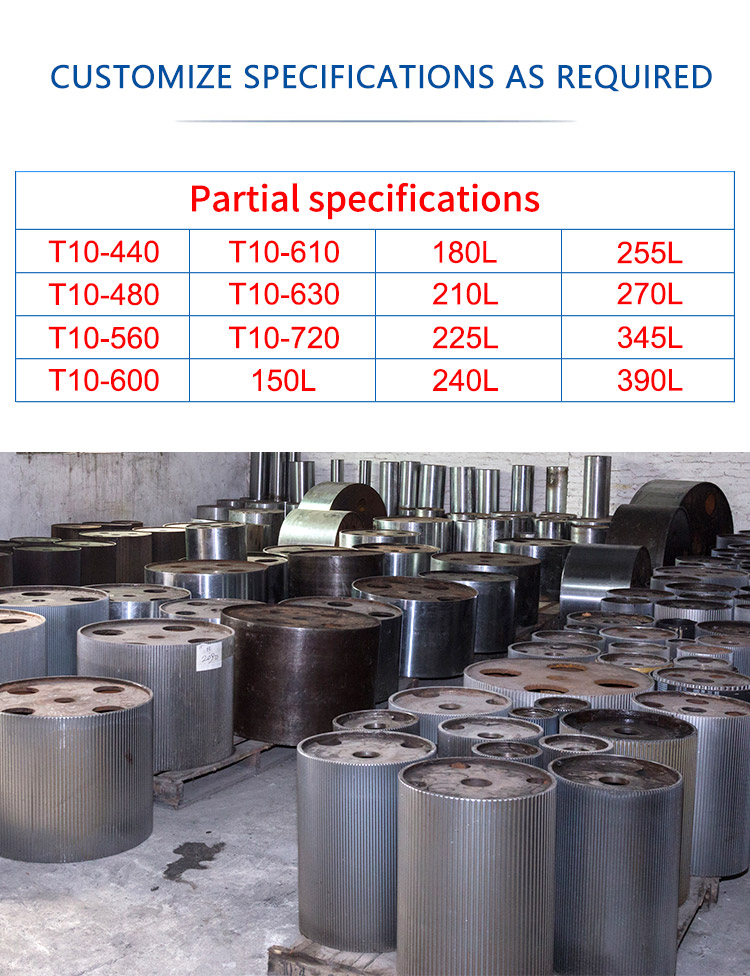

The mold is complete, all kinds of tooth shape,

specifications, color/thickness of the added rubber

can be customized!

Yonghangbelt offers a wide range of high quality Draw Down Belts for the packaging industry.

These manufactured toothed belts come complete with a backing on the top surface to help vertically draw down film in packaging machines to make bags.

A complete range of moulded, seamless backings is available along with comprehensive machining, drilling & milling operations.

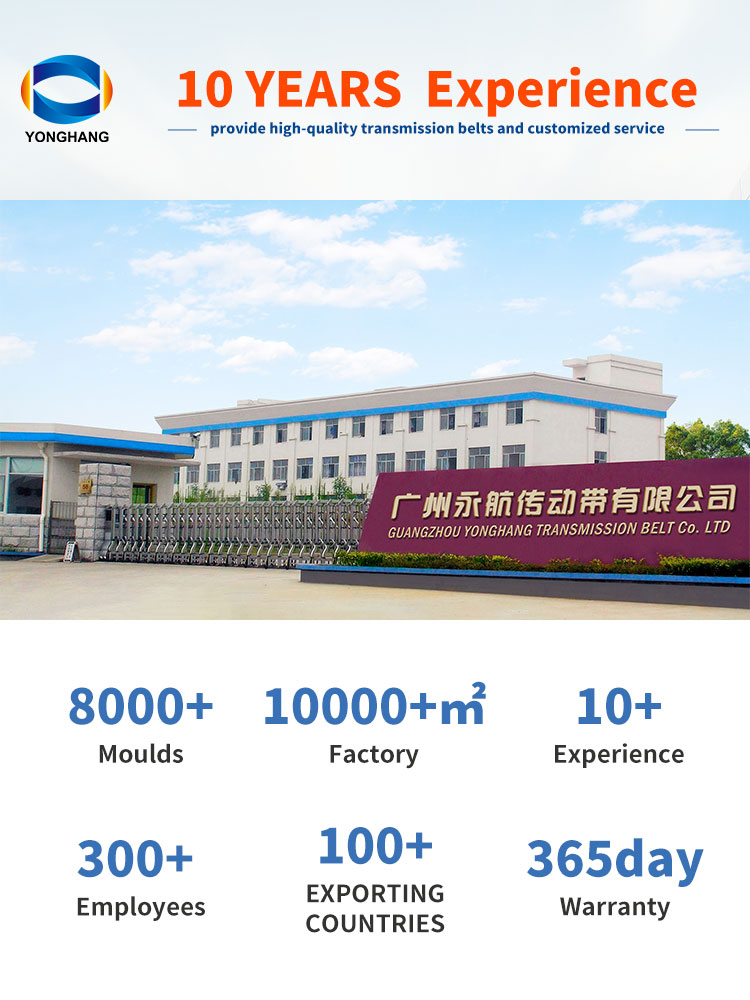

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details