Customized ATK polyurethane punching of holes transmission toothed timing belt manufacturers

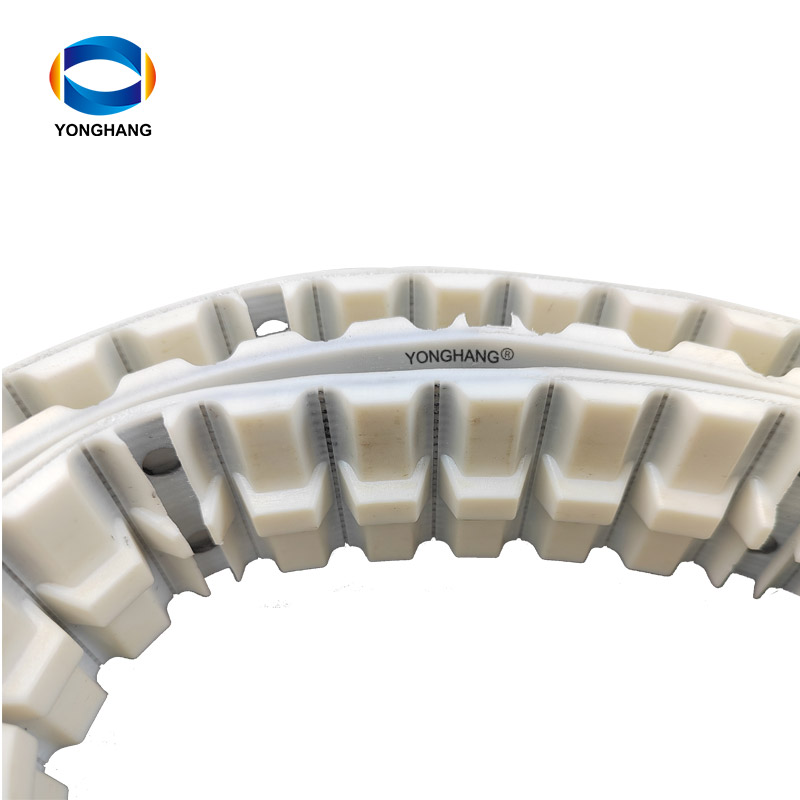

ATK polyurethane toothed timing belts are made of thermoplastic polyurethane with a high resistance to wear and tear, various types of reinforcement cores to ensure that they retain their good capacity during rotation and are produced with tight tolerances. A layer of nylon is added to the tooth face or back of the teeth during production to ensure that the special characteristics of the belt remain unchanged in special applications. A thick layer of polyurethane can also be added to the back of the belt to protect it against corrosion and high loads.

ATK timing belt is manufactured from thermoplastic polyurethane material, offering high abrasion resistance. No recycled materials are added, ensuring superior quality. Its surface can undergo specialized processing as required, including thickened transparent PU coating, offering anti-slip, eco-friendly, and wear-resistant properties.

Utilizing a PU steel wire core as the tension layer, the ATK timing belt delivers enhanced tensile strength, effectively preventing elongation and achieving a 35% increase in tensile resistance. The tooth surface incorporates guide strips in 5×8, 6×10, and 8×13 specifications to secure alignment and prevent misalignment.

Additionally, the ATK timing belt offers multiple custom options: - Fabric-covered teeth/NFT/PAZ - Fabric-covered back/NFB/PAR - Double-sided fabric covering/NFT+NFB/PAZ+PAR - Protective coating/Coating - Double-sided teeth/Double-sides tooth To meet diverse machine requirements, various processing types are available, including double-sided teeth, perforation, adhesive-coated grooving, thickened PU, adhesive-coated fabric-covered teeth, and patterned surfaces.

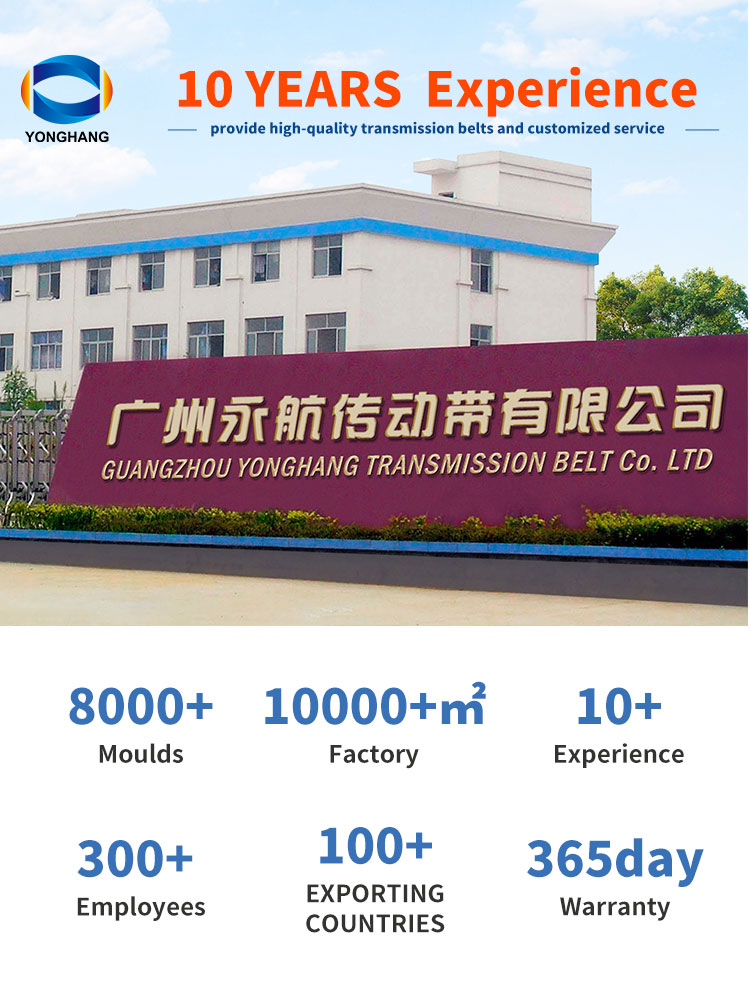

Contact Details