YONHANGBELT PU Endless ATN10/ATN20/ATN12.7 ATN Timing Belt

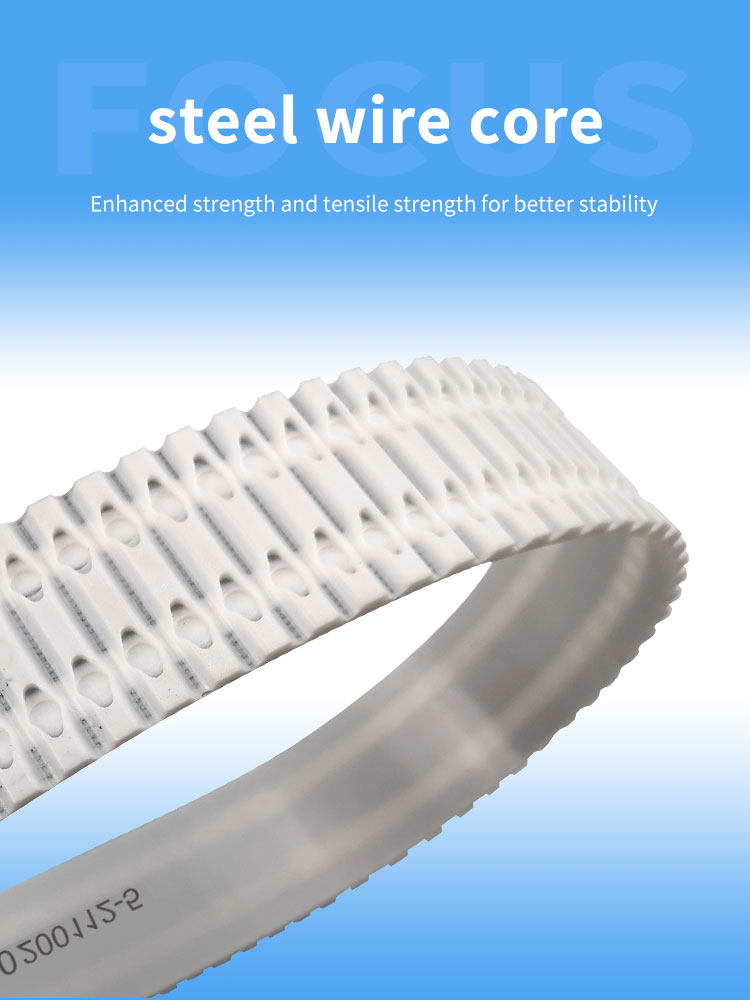

ATN10 timing belt made of high quality polyurethane material and high quality steel wire through special molding process.

Wear resistance and shear resistance.Combined with various kinds of steel wire to enhance the strength of the belt,

tensile resistance, so that the belt has a good dimensional stability.The polyurethane ring type power belt has small tolerance,

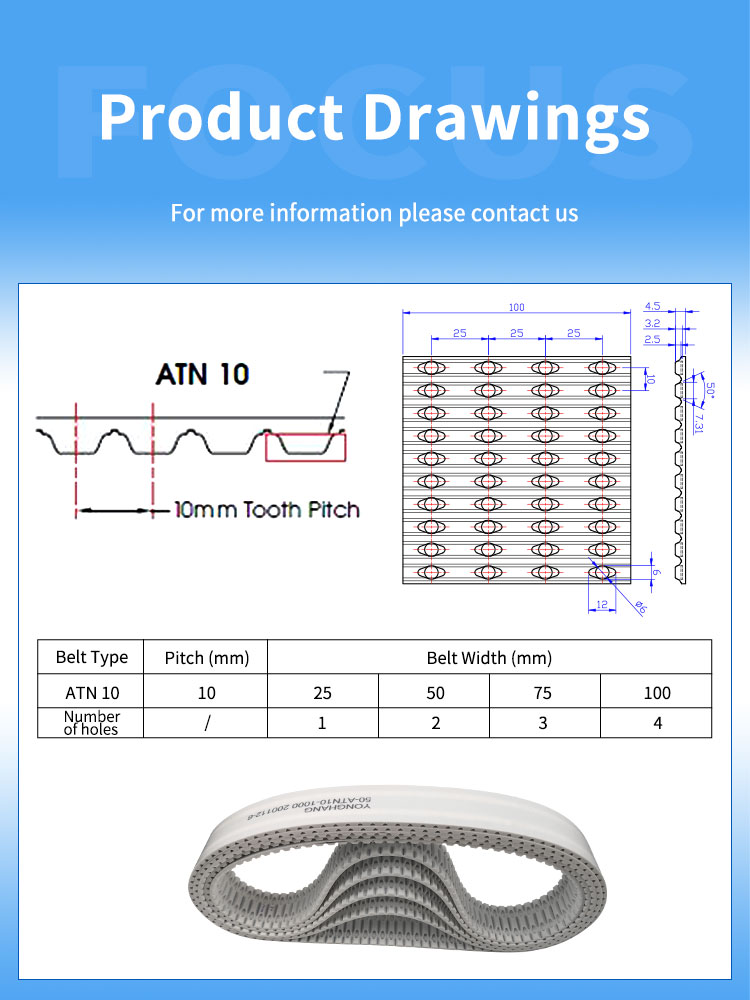

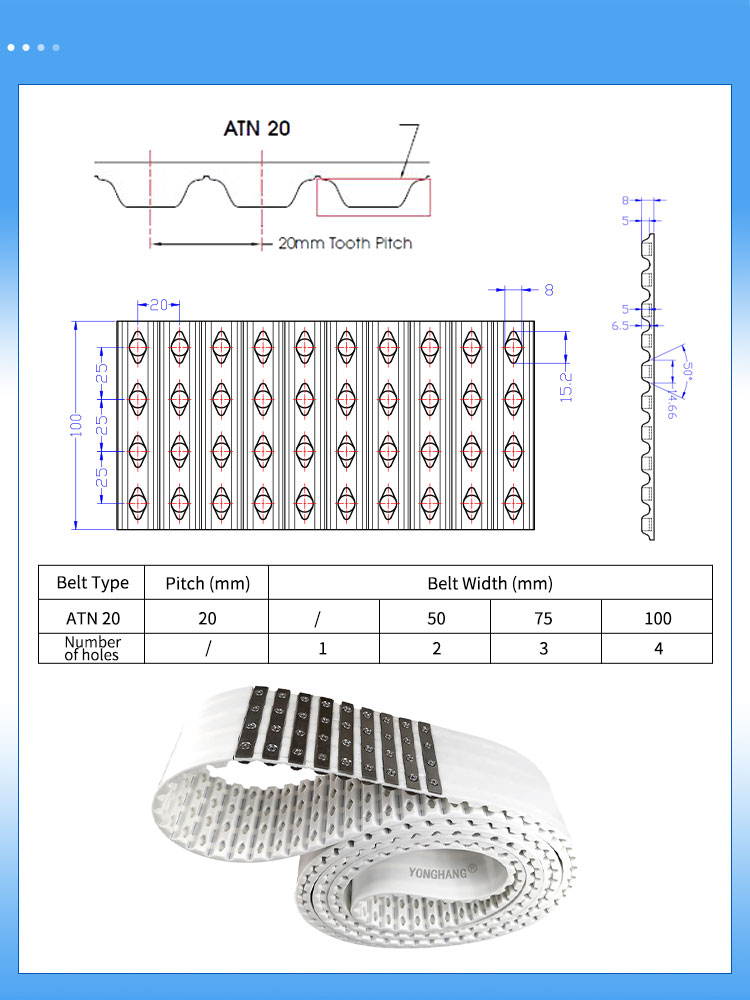

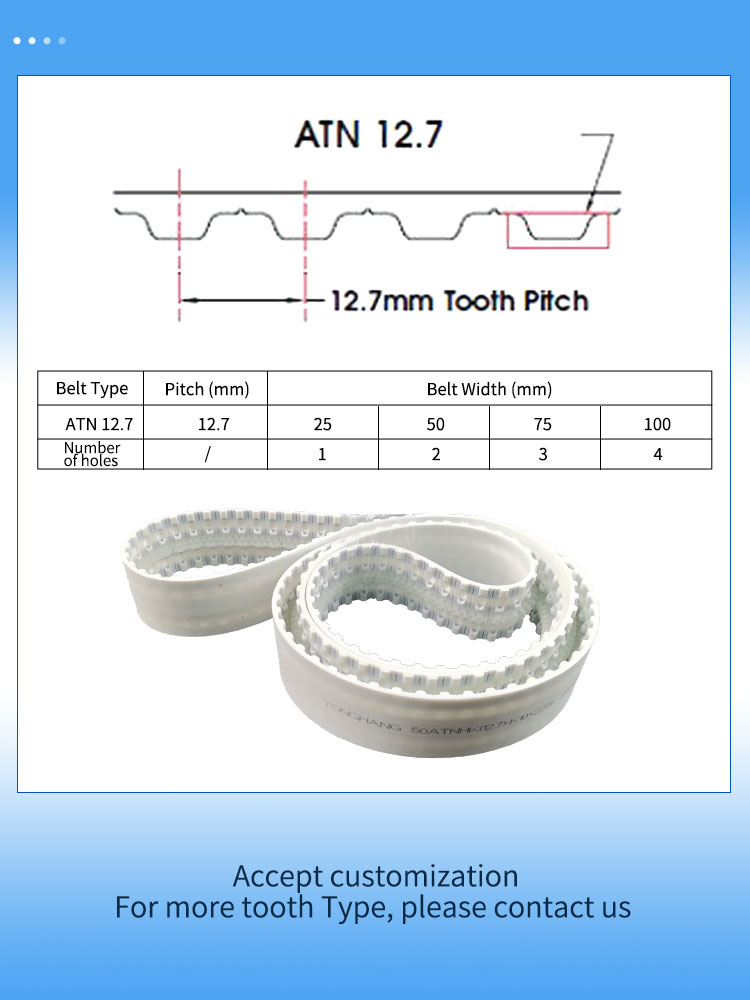

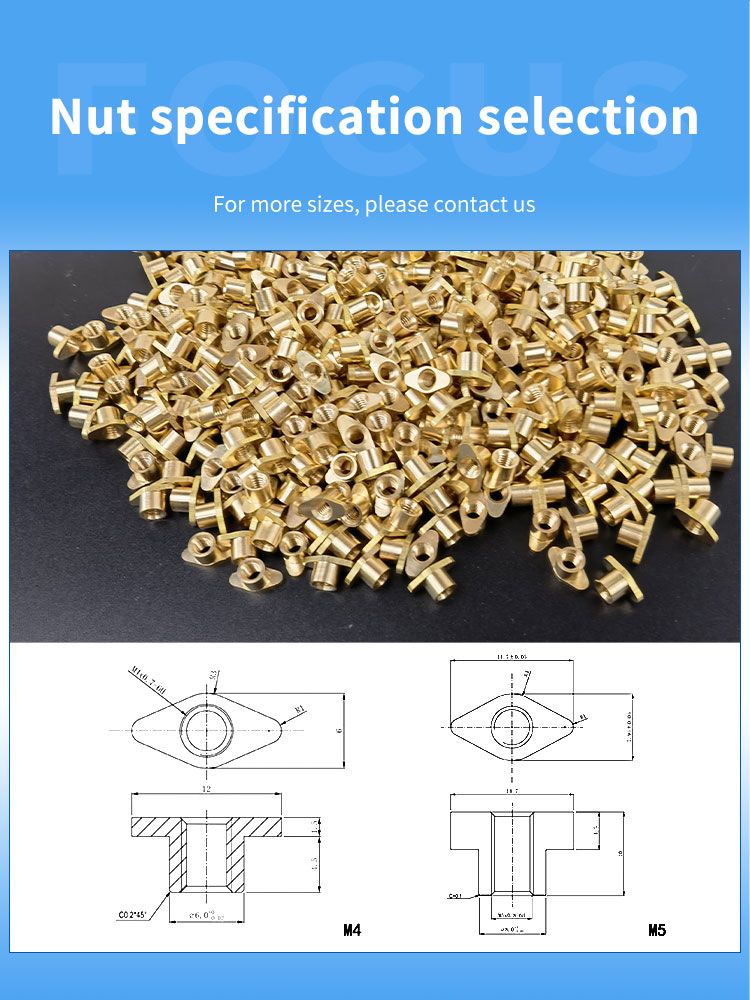

which can ensure the accuracy of thickness and length.Tooth surface reserved diamond countersunk hole, back can be fixed with screws block,

steel wire core and fiber core two kinds of tensile layer, can provide seamless belt, open belt or with joint belt.

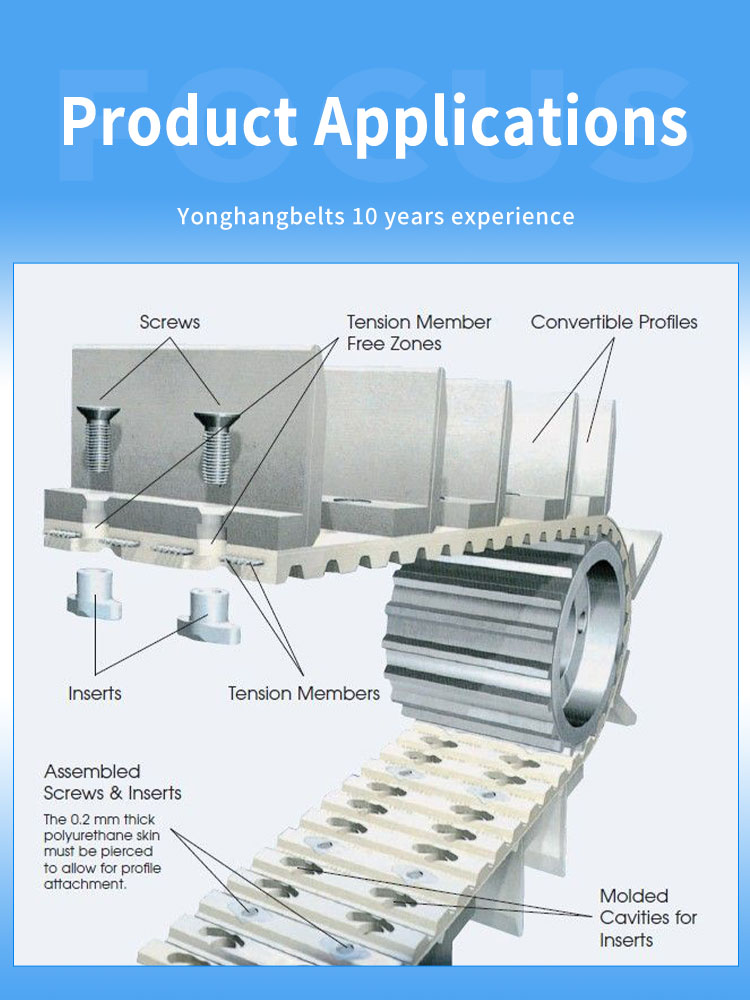

Most advanced profile ATN10 timing belt system utilizing molded belt cavities and specially designed inserts allowing

users to fasten profiles or profile nests using screws and simple hand tools. ATN10 Belts are an innovation in profiled timing belts.

ATN10 /ATN12.7/ ATN20

Polyurethane, steel reinforced, modular flight system belting

High Power AT Profile in metric pitch with trapezoidal toothform

ATN belting is extruded on a form wheel with insert holes on every tooth spacing

ATN components available in nylon, brass, and stainless steel

Color : White etc

Material: PE/Poly Ethylen, Steel reinforced, Fabric, Kevlar cord.

Mechanical properties: Dimensional stability; Strong low; Low noise; High wear resistance; No need to maintain; High elastic

Working temperature: 30°C to +80°C, Instant high temperature: +80°C

Working Pressure: ≤32Mpa Bud -Shape Ring≤50Mpa

Performance: Aging proof, waterproof, prevent UVA, Ozone-resistant, highly resistant to oil, acid and alkali corrosion resistance

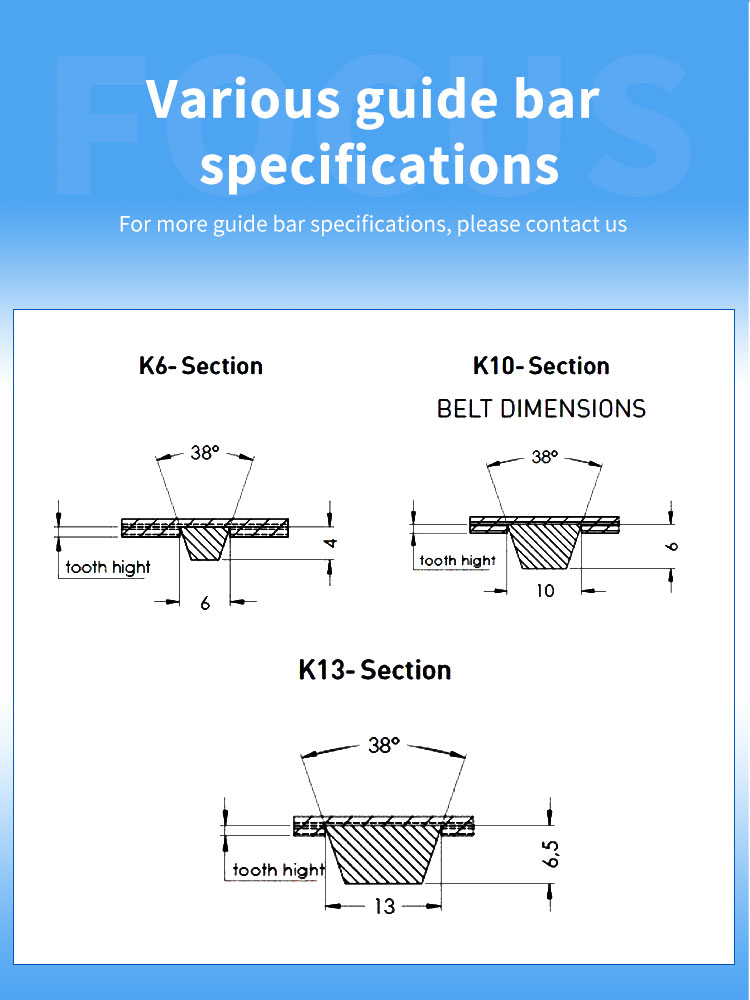

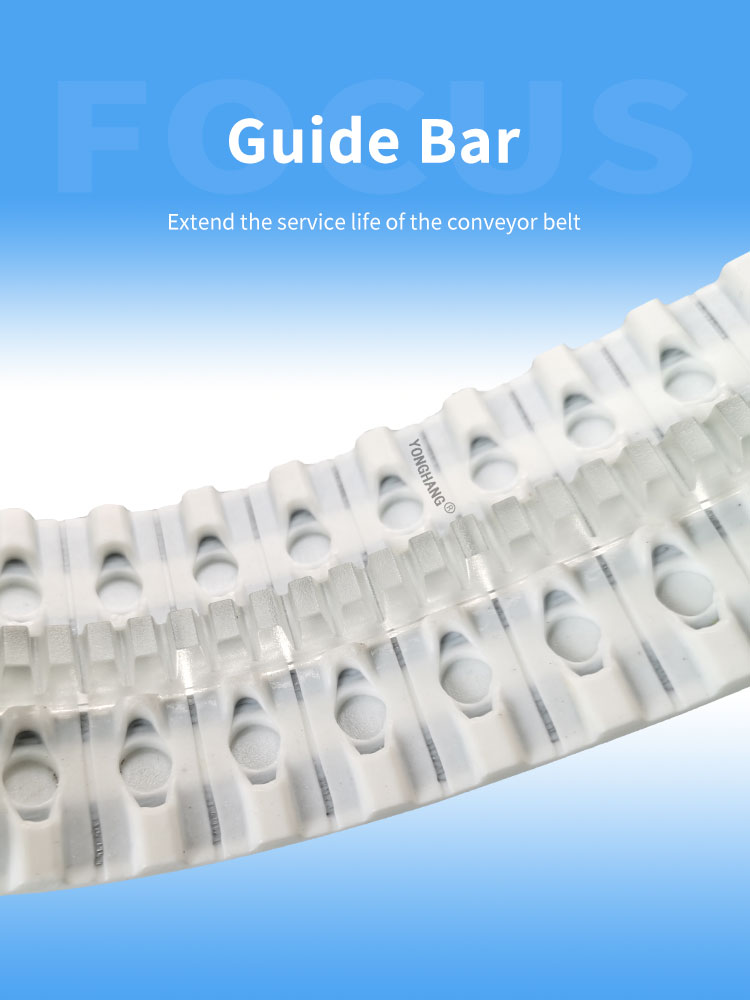

Processing: grooving /punch/ slot / pattern / block / guide bar / profile

Use (for machines): Stone, ceramic,glass,electronics,aluminum,tobacco, textile, logistics,printing,packaging,paper products processing industries etc.

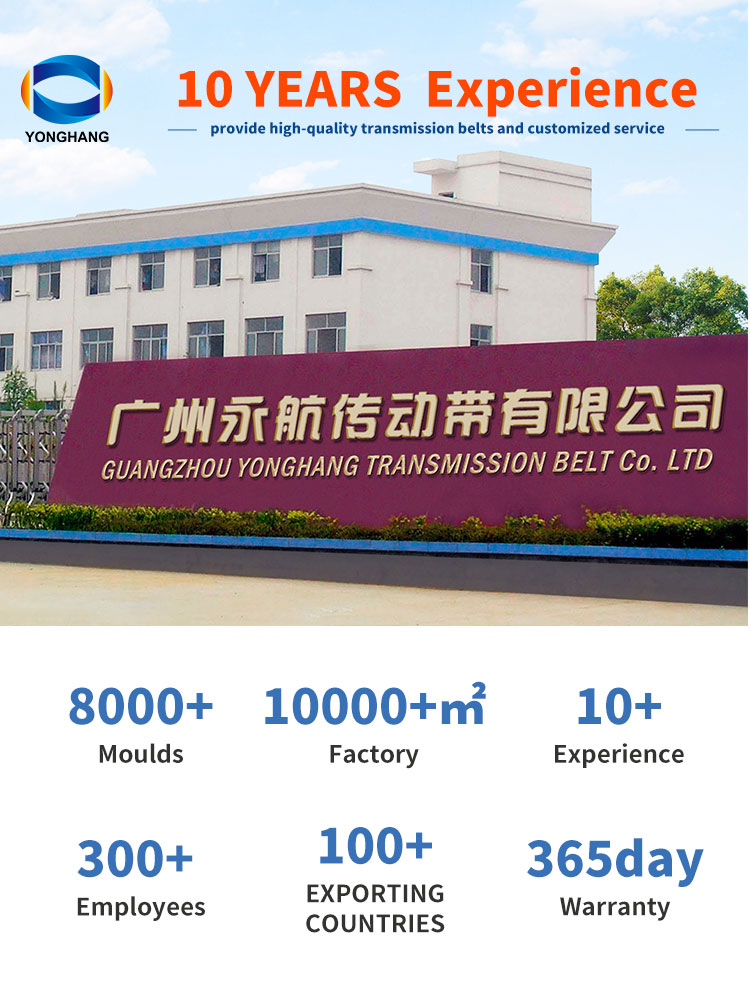

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

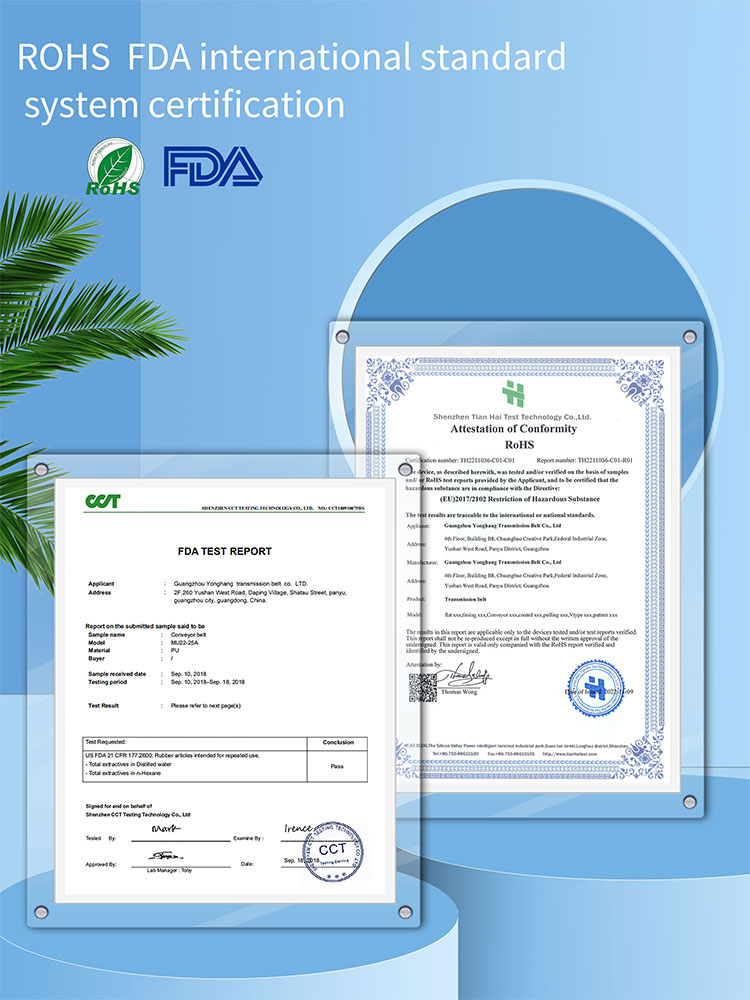

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details