12 Years Transmission Belts Coating Customized Factory.

industrial Extrusion power transmission belts puller Haul Off rubber Multi Wedge Drive belts with Coated

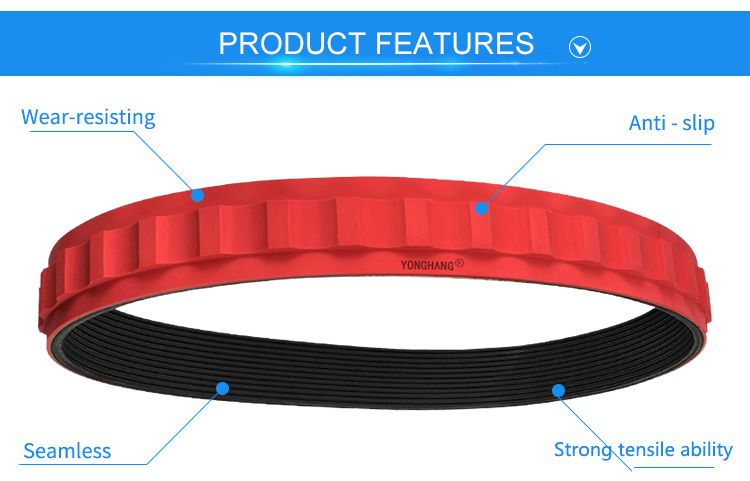

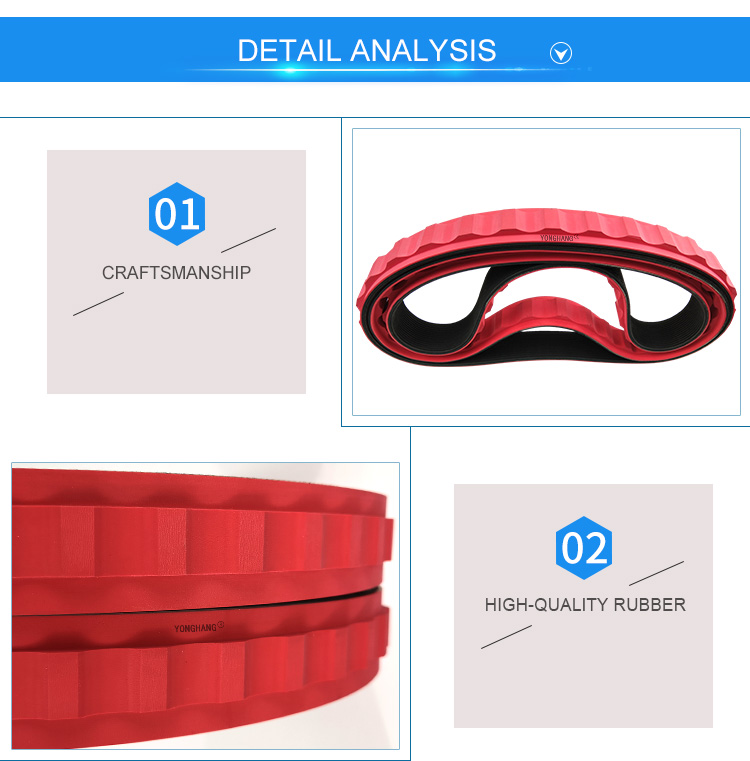

Seamless belt construction and the development of traction belt is we have been following the manufacturing standard, we can be on the surface of the flat belt, Timing belt, multi-wedge belt - body vulcanization of different rubber or PU coating.Depending on our experience in the special industry and technical research and development, we have become one of the most wear-resistant belt manufacturers in China.

Special processing slotting traction machine belt adopt seamless integrated vulcanization molding,Without layering, without cracking, the surface is specially grooved as required.

Application:

Aerospace, military, shipbuilding, cable manufacturing, wire traction

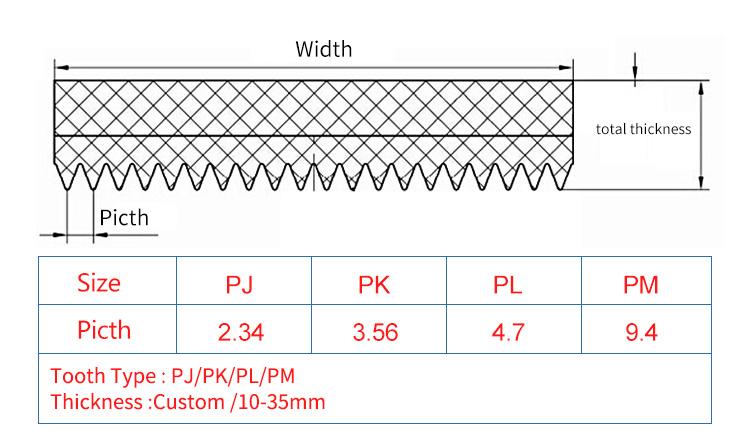

| Specification(Inner Length, Width, Thickness) | Customization |

| Ribs type | PK /PJ/PL/PM |

| Color | Red |

| Traction Layer | Rubber: Imported NR |

| Bottom layer | Rubber: CR ;neoprene |

| Reinforcement | Polyester Cord + Fabric |

Mechanical Properties

| High breaking load; High Wear Resistance; Low Elongation at Working Load; Aging Proof |

| Hardness | 60-85°± 5°(cable traction) 60-85°± 5°(optical cable; plastic and pipe Traction etc.) |

| Max. temperature | +100℃ |

| Processing | Rubber Mixing, Winding,Rubber Adding, Cutting,Grinding, QC, Packaging and Delivering |

| Application | Cable, Optical cable, Plastic, Rubber tube, Pipe, Seal and Packaging industry etc. |

Contact Details